设计单位 深圳大学建筑设计研究院元本体工作室

EPC单位 中建科工集团有限公司

项目地点 广东湛江

建成时间 2021年12月

建筑面积 68606平方米

本文文字由深大建筑设计院元本体工作室提供。

本项目为湛江市重点民生工程之一,旨在满足中低层收入社会劳动者(如清洁工、公交司机等)的居住需求,为其提供高品质的公共租赁住房,以提升劳动者幸福感,体现社会公平性。

This project is one of the key livelihood projects in Zhanjiang City. It aims to meet the housing needs of low- and middle-income social workers, such as cleaners and bus drivers, by providing them with high-quality public rental housing. The goal is to enhance the happiness of workers and reflect social equity.

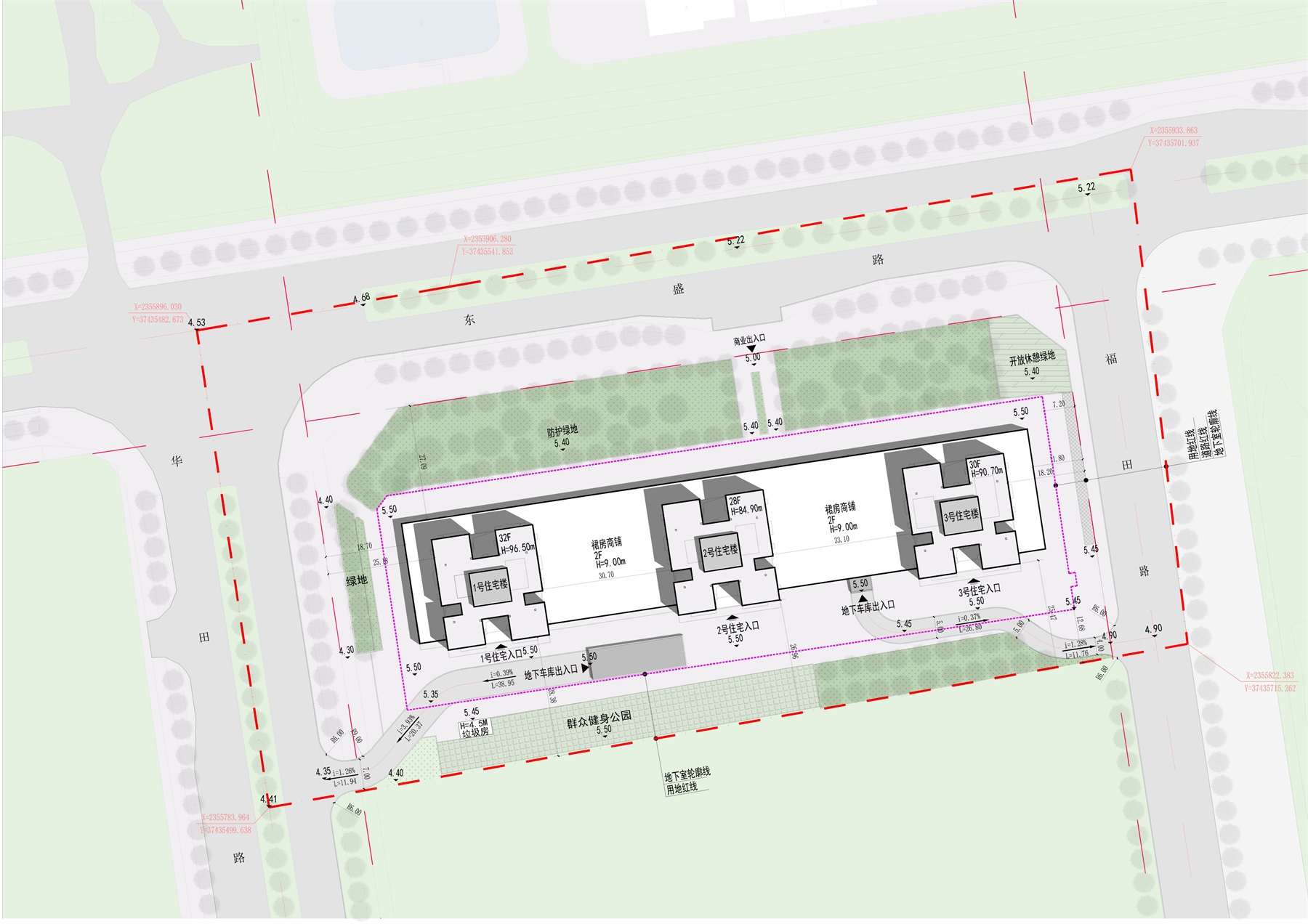

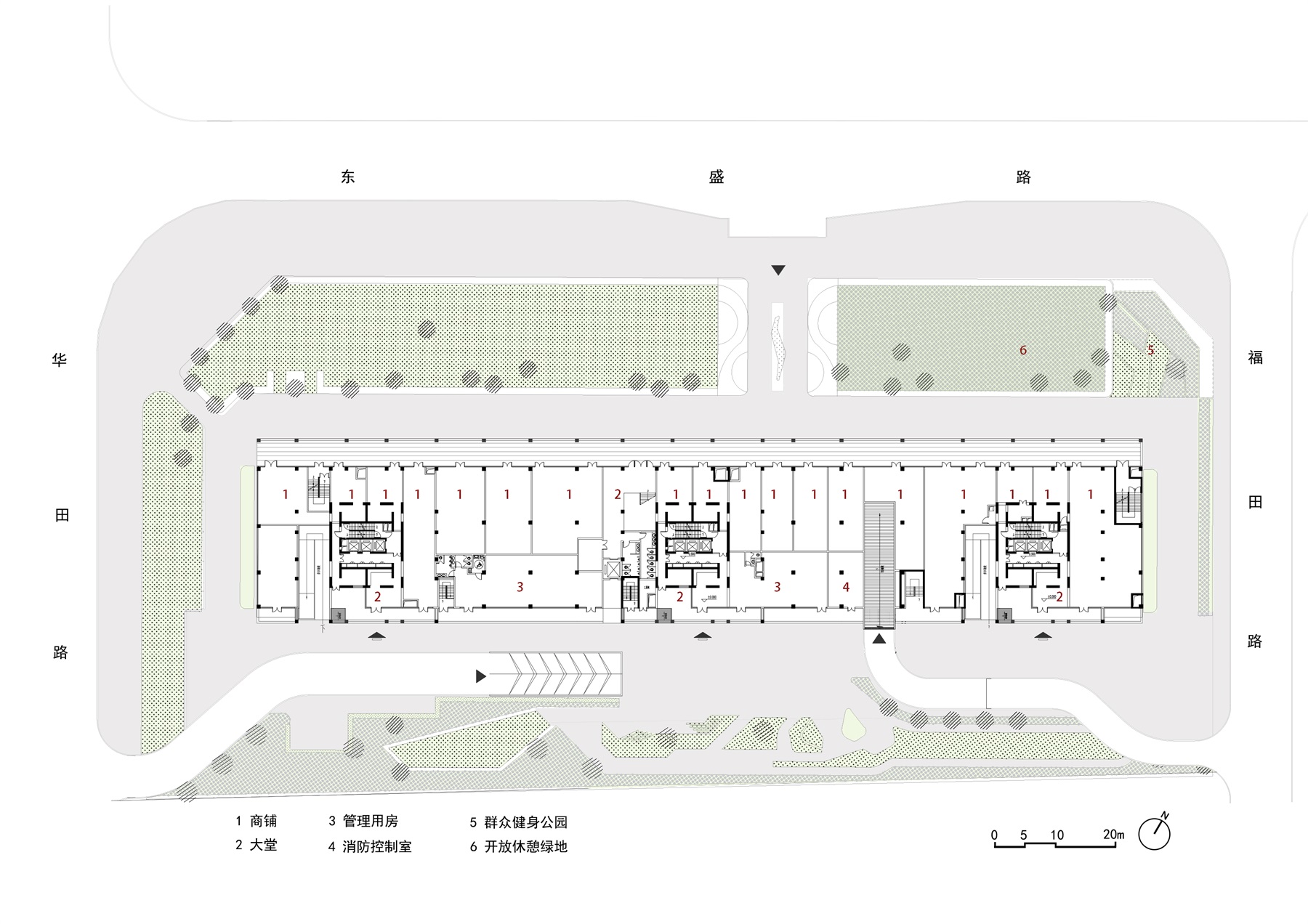

项目位于湛江市赤坎区东盛路南侧,东临福田路,西临华田路。基地呈长条状,东西长175米,南北宽84米,场地平整。北部为水质净化厂,东、南、西侧为已建成高层住宅区。北侧面向湾景,景观视线良好,周边交通便捷。

The project is located on the south side of Dongsheng Road in Chikan District, Zhanjiang City, with Futian Road to the east and Huatian Road to the west. The site is rectangular in shape, 175 meters long from east to west, and 84 meters wide from north to south, with a flat terrain. The northern part is a water purification plant, while the east, south, and west sides are high-rise residential areas that have already been built. The northern side faces the bay with good landscape visibility, and the surrounding transportation is convenient.

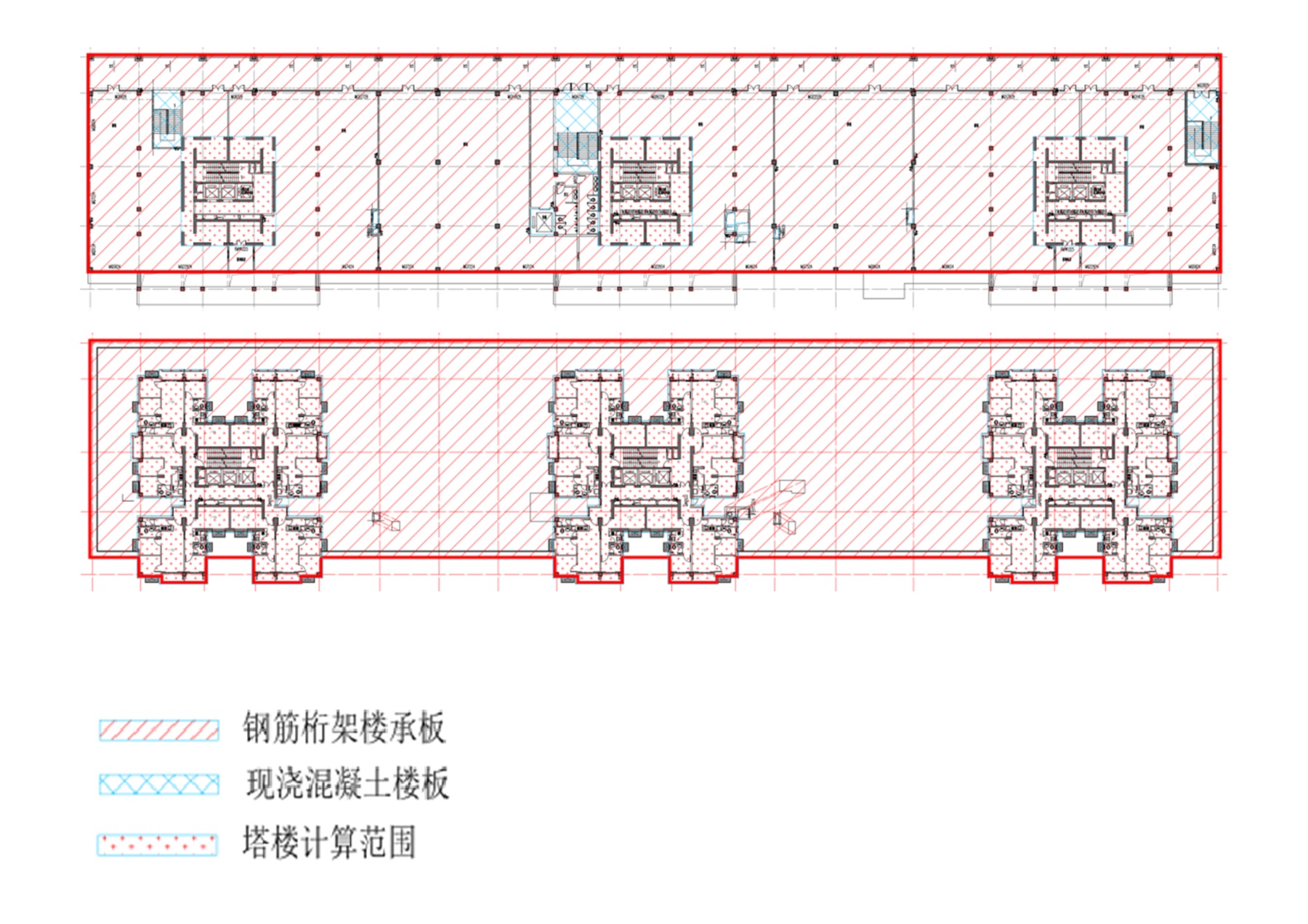

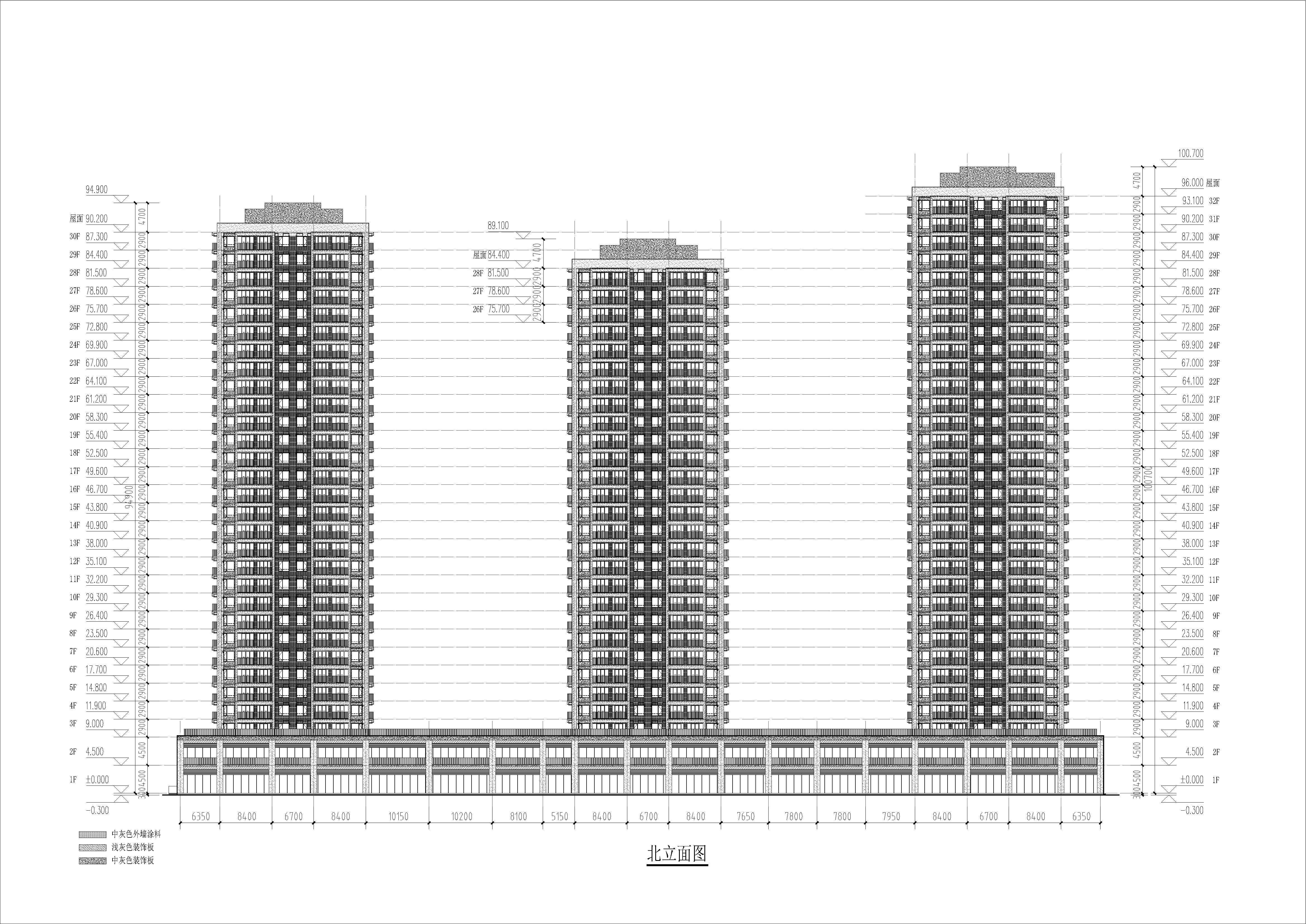

规划用地面积24885平方米,总建筑面积 68606平方米。沿东盛路南侧展开布置三栋高层塔楼住宅,高低错落。底部三层裙房为商业配套服务设施。住宅产品以45平方米与60平方米的小户型为主,拥有良好的自然通风采光和景观朝向。

The planned land area for the project is 24,885 square meters, with a total construction area of 68,606 square meters. Three high-rise tower residential buildings are arranged along the south side of Dongsheng Road in a staggered pattern. The bottom three floors are commercial facilities for supporting services. The residential products mainly consist of small units of 45 square meters and 60 square meters, with good natural ventilation, lighting, and landscape orientation.

本项目作为住建部和广东省住建厅钢结构装配式住宅的重要试点工程之一,并非采用传统钢筋混凝土结构,而是采用钢结构+装配式预制构件的形式。

This project is one of the important pilot projects for steel structure assembled housing of the Ministry of Housing and Urban-Rural Development and the Housing and Construction Department of Guangdong Province. It does not adopt traditional reinforced concrete structures, but instead uses steel structures and prefabricated components for assembly.

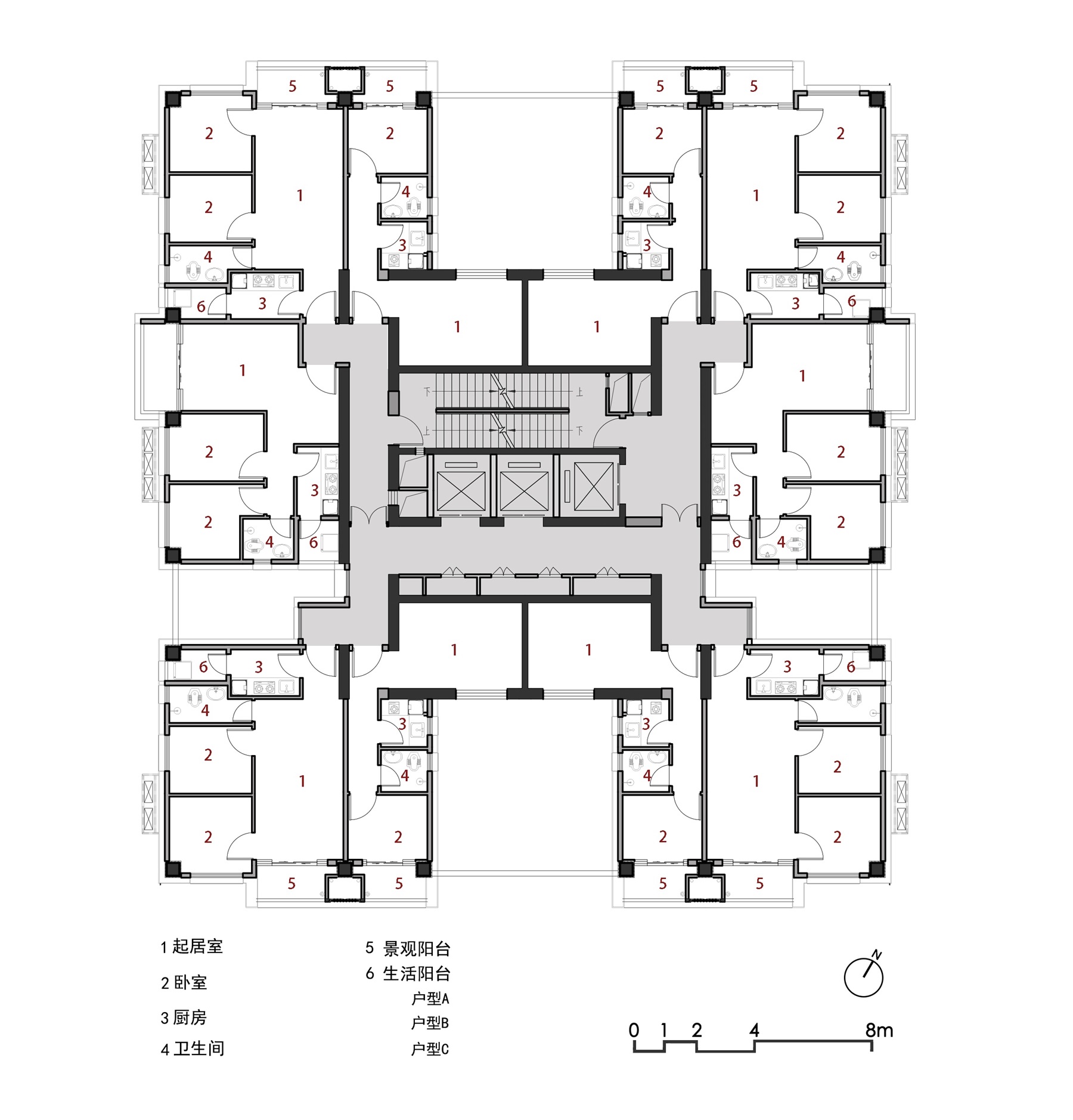

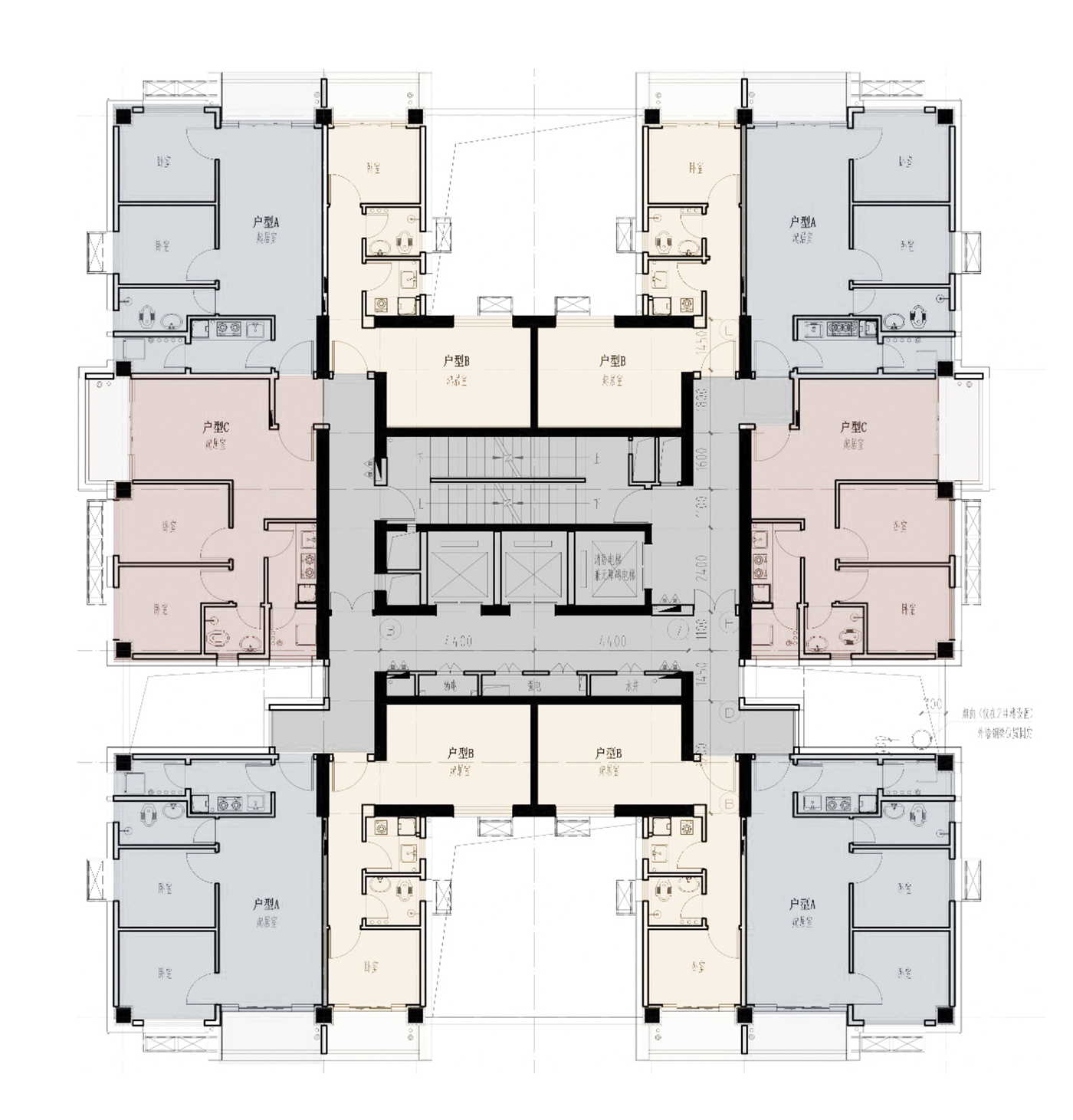

建筑平面设计符合钢结构体系特点进行平面布置,采用各功能模块及模块组合的设计方法,模块应进行优化组合,并应满足功能需求及结构布置要求;平面规则、平整,采用对称式布置方式;楼电梯及设备坚井等区域独立集中设置;空间分隔与结构梁柱布置相协调,空间布局考虑结构抗侧力体系的布置。

The architectural layout is designed in accordance with the characteristics of the steel structure system, using a design method that combines various functional modules and module combinations. The modules should be optimized and combined to meet functional requirements and structural layout requirements. The layout is regular, flat, and uses a symmetrical arrangement. Elevator and equipment shafts are independently and centrally located, while space partitioning is coordinated with the structural beam and column layout, and the spatial layout considers the arrangement of the structural lateral force resistance system.

套型设计遵循定型化、系列化原则,采用标准化套型设计,大开间结构布置的方式,满足套内空间布置的灵活性、可变性,同时满足标准化、模块化、系列化及可组合的要求。

The design of the apartment layout follows the principles of standardization and serialization, using standardized apartment designs with a large open-plan layout to provide flexibility and variability in interior space while meeting the requirements for standardization, modularization, serialization, and combination.

建筑立面设计符合湛江市气候特征条件,采用标准化与多样性相结合的方法,采用保温隔热性能良好的一体化墙板及配套的饰面材料,满足耐久性要求。外墙板、外门窗、阳台板、幕墙、空调板、遮阳设施及装饰等通用部品部件采用标准化设计,建筑立面形状规则、均匀,风格简洁现代。

The architectural facade design conforms to the climate characteristics of Zhanjiang city, using a combination of standardization and diversity. Integrated wall panels with good thermal insulation performance and matching decorative materials are used to meet durability requirements. Common parts such as exterior wall panels, doors and windows, balcony panels, curtain walls, air conditioning panels, sun shading facilities, and decorations are designed with standardization in mind, and the shape of the building facade is uniform and modern with a simple style.

钢结构装配式实施建造体系符合绿色低碳、节能环保要求,传达建筑全寿命周期可持续发展的理念。

The implementation of the steel structure assembly construction system conforms to the requirements of green, low-carbon, energy-saving and environmental protection, and conveys the concept of sustainable development throughout the entire life cycle of the building.

项目位于台风侵扰的高风压地区,高层钢结构装配式的住宅体系设计,面临着如下挑战:

The project is located in a high wind pressure area that is frequently affected by typhoons. The design of the high-rise steel structure assembly residential system faces the following challenges:

(1)小户型产品与钢构体系的适配性与可变性

(2)高风压地区高层建筑的结构舒适性

(3)性能化的构造体系

(4)定型化、标准化的装配式设计

(5)成本可控下的设计与施工、运营一体化绿色建造

(1) The adaptability and variability of small unit products with steel structure system.

(2) Structural comfort of high-rise buildings in high wind pressure areas.

(3) Performance-oriented structural system.

(4) Standardized assembly design.

(5) Integrated green construction with design, construction, operation, and cost control.

小户型适应钢结构体系

Adaptability and versatility of small-sized units to steel structural systems

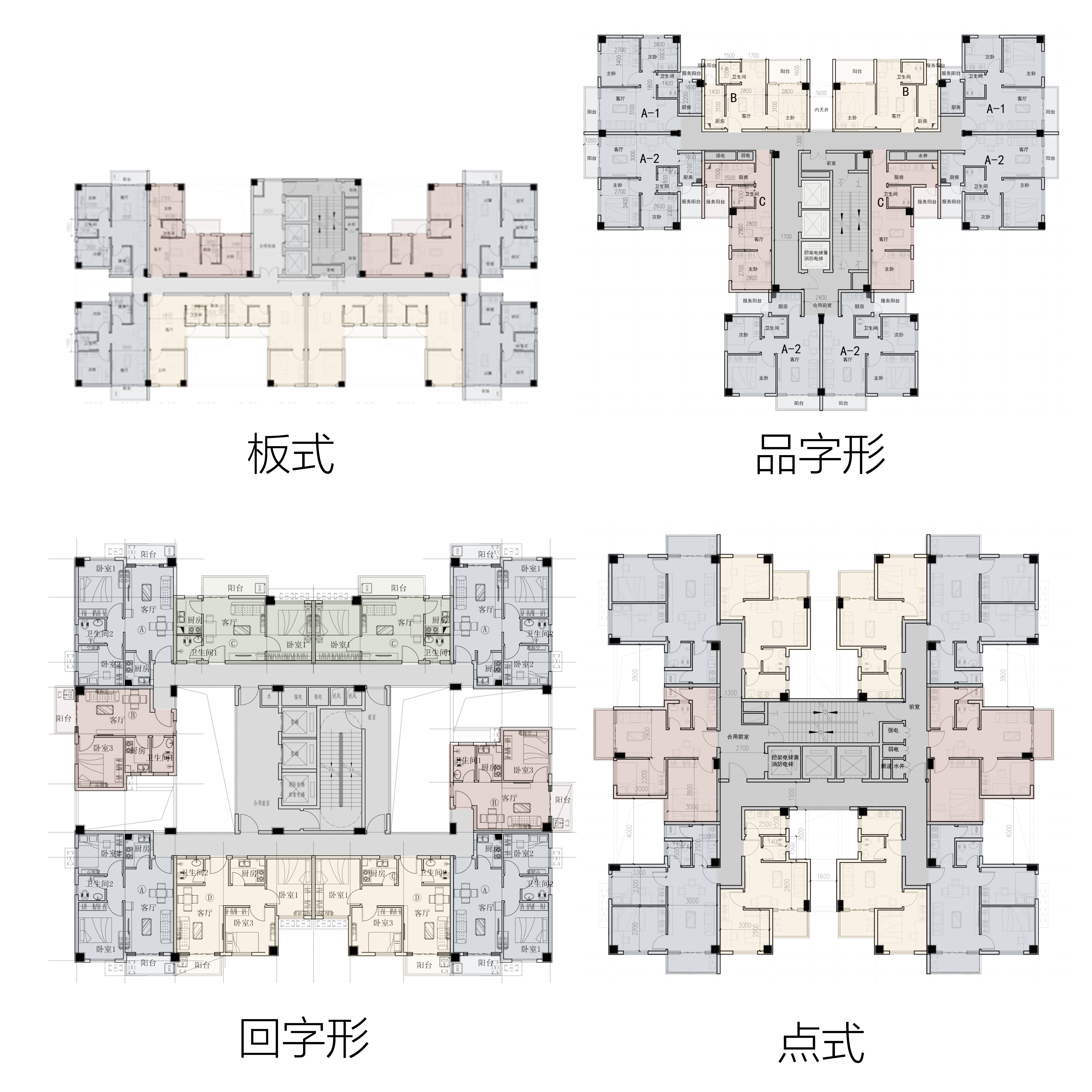

为了满足小户型产品与钢构体系的适应性,我们根据建筑使用功能需求、结构安全性指标(例如层间位移角和舒适度等)以及经济性指标,经过平面方案比选,选用点式平面方案。点式平面的优点在于其外轮廓方正完整,凹凸变化少,有利于结构支撑的布置。

To meet the adaptability of small-unit products with a steel structure system, we have selected a point-type layout through a comparison of floor plan schemes based on the requirements of the building's functional use, structural safety indicators (such as inter-story displacement angle and comfort), and economic indicators. The advantage of a point-type layout is that it has a complete and square outline with minimal concave-convex changes, which is conducive to the arrangement of structural support.

可变户型适应多样使用需求

Adaptable unit layouts to accommodate diverse usage needs

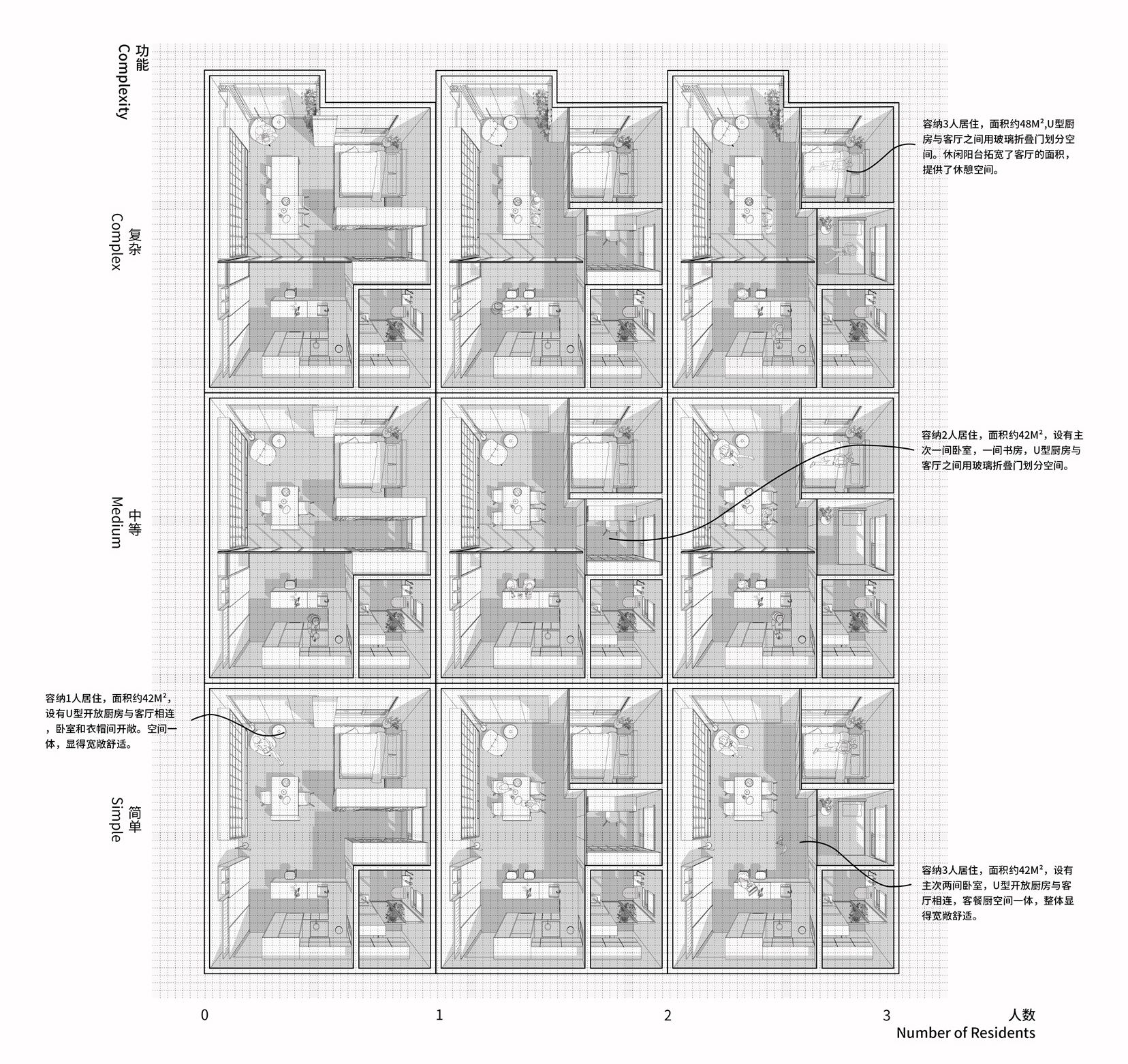

钢结构体系之下,我们对竖向结构进行优化,保证户型内部无结构性墙柱布置,为未来的空间改造与提升提供条件,使其具有更好的适应性与可变性。标准化的三种户型,尺寸合理,采光良好,厨卫集中,方便管线布置。户型之间可以进行组合,将60平方米与45平方米的户型组合成105平方米的新户型。户型内部通过隔墙的变化,实现一居室与两居室的转化,灵活变化的空间模式适应不同居住人数与功能需求。

Under the steel structural system, the vertical structure is optimized to ensure that there are no structural walls or columns inside the apartment, providing better adaptability and flexibility for future space renovation and enhancement. Three standardized apartment layouts are designed with reasonable sizes, good lighting, centralized kitchen and bathroom, and convenient pipeline layout. The apartment layouts can be combined, such as combining a 60㎡ and a 45㎡ apartment to create a new 105㎡ apartment. By changing the location of the partition walls inside the apartment, the layout can be transformed from a one-bedroom to a two-bedroom, providing a flexible space pattern that can adapt to different numbers of residents and functional needs.

配套设计无障碍户型

Design of Accessible Housing with Supporting Facilities

发挥户型可变性的优势,通过调整厨房、卫生间、走道尺寸,减少一个卧室,提供无障碍单人户型,满足无障碍使用者的使用需求。

Taking advantage of the flexibility of the adaptable layout, the design adjusts the size of the kitchen, bathroom, and corridor to reduce one bedroom, providing a barrier-free single-person unit that meets the needs of people with disabilities.

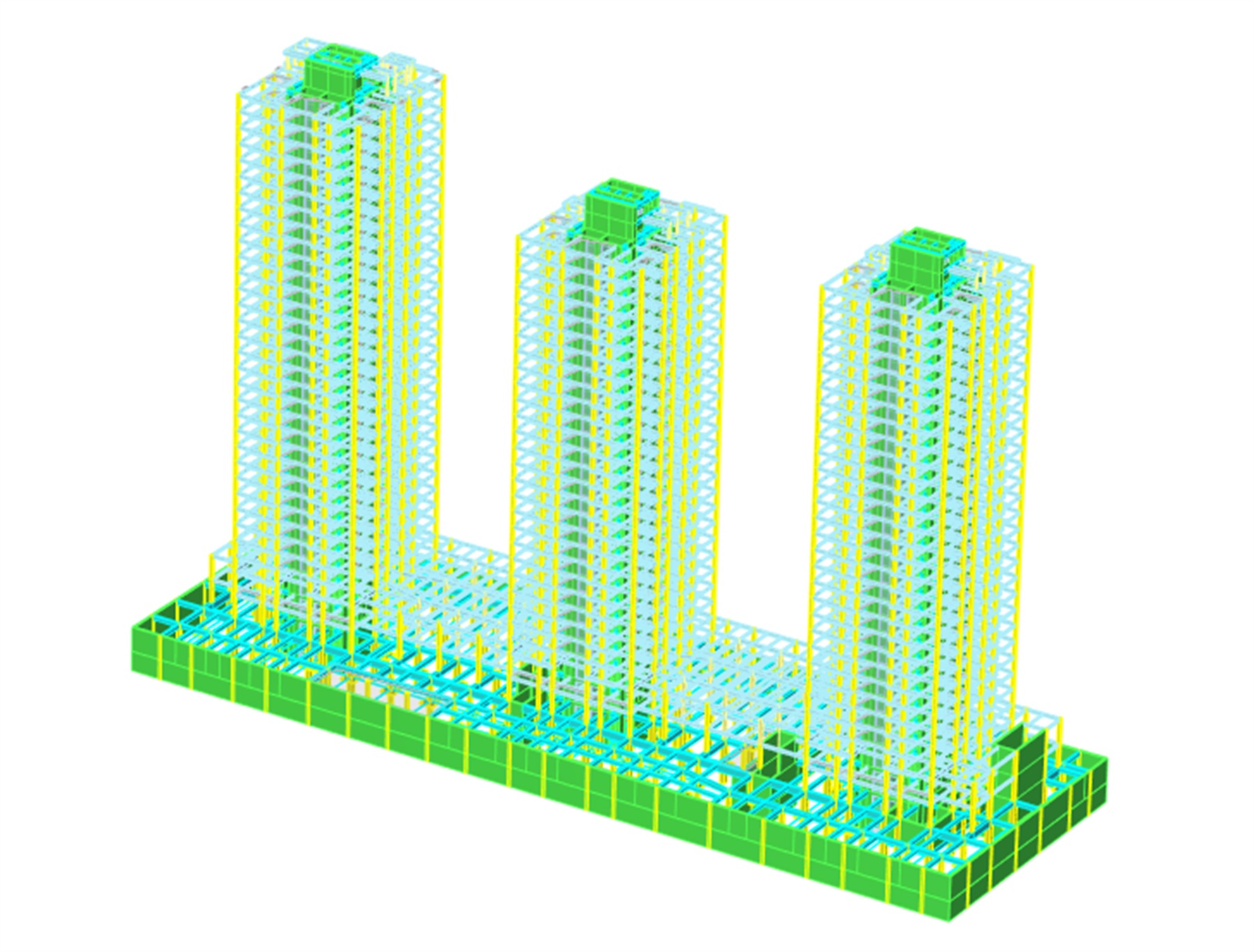

钢框架-混凝土核心筒结构体系

steel frame-concrete core tube structural system

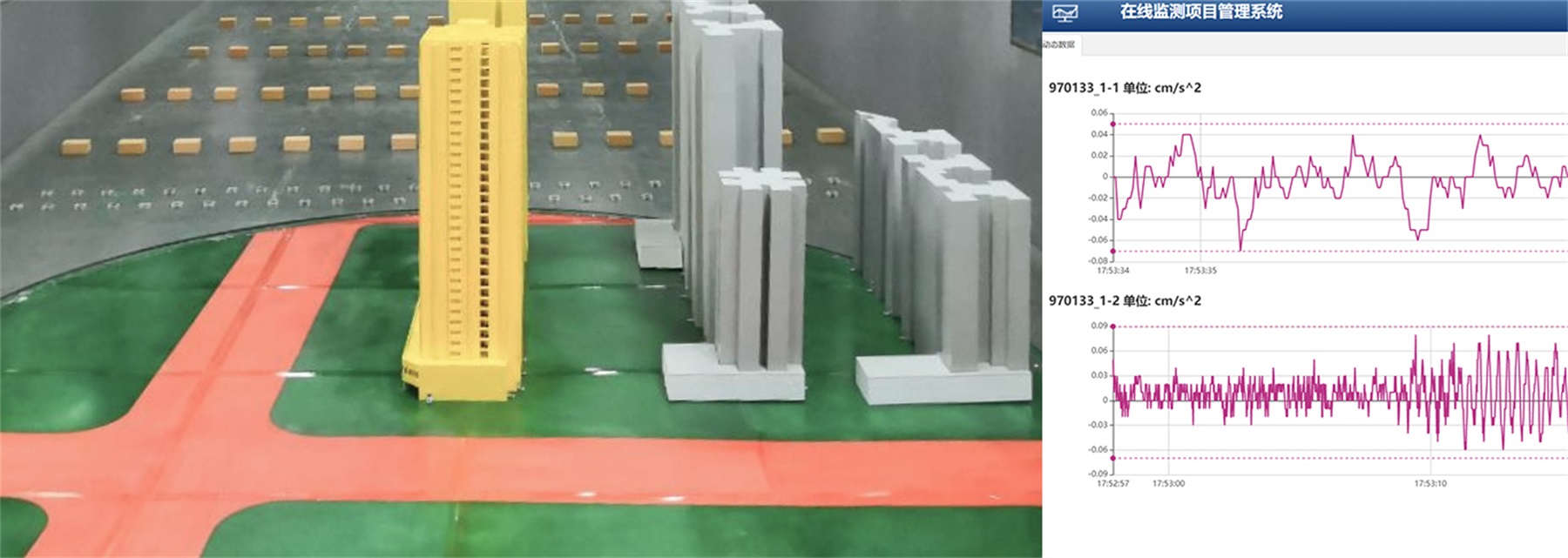

为满足装配式钢结构的建造,保证高风亚地区的结构舒适性,我们首先通过平面方案比选确定点式平面;再通过YJK软件对钢框架—中心支撑结构、钢框架—混凝土核心筒、钢框架—钢板剪力墙进行分析,并对三种结构布置进行比较,以选择顶点风振加速度值最小,且经济性指标较好的方案。最终,通过YJK模型、Midas模型、风洞试验的分析振动频率、振动加速度和振动持续时间,我们最终确定采用钢框架—混凝土核心筒结构体系,以实现风震舒适度的最大化。

To meet the construction of the assembled steel structure and ensure the structural comfort in high-wind areas, the point-type plan was first determined through plan comparison. Then, using the YJK software to compare the steel frame-core concrete tube structure, steel frame-steel plate shear wall, and other structures, the steel frame-core concrete tube structure had the smallest peak wind-induced acceleration value and required less steel. After comparing three or four different structural layouts, the option with the smallest peak wind-induced acceleration value and better economic indicators was selected. Finally, using analysis of vibration frequency, vibration acceleration, and vibration duration with YJK model, Midas model, and wind tunnel testing, the scheme that satisfied wind comfort was selected. The final decision was made to adopt the steel frame-core concrete tube structure system.

竖向结构构件

Vertical structural components

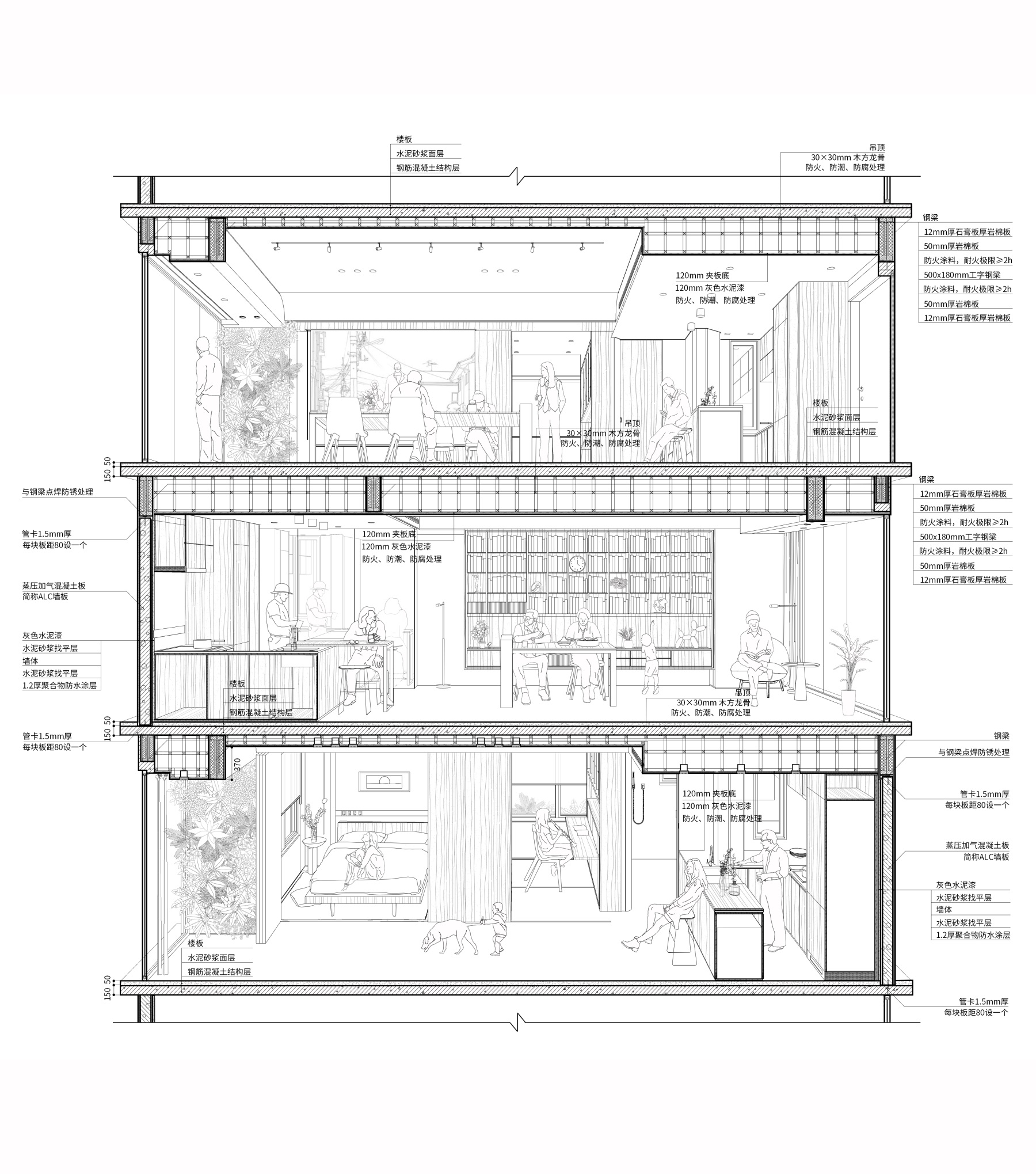

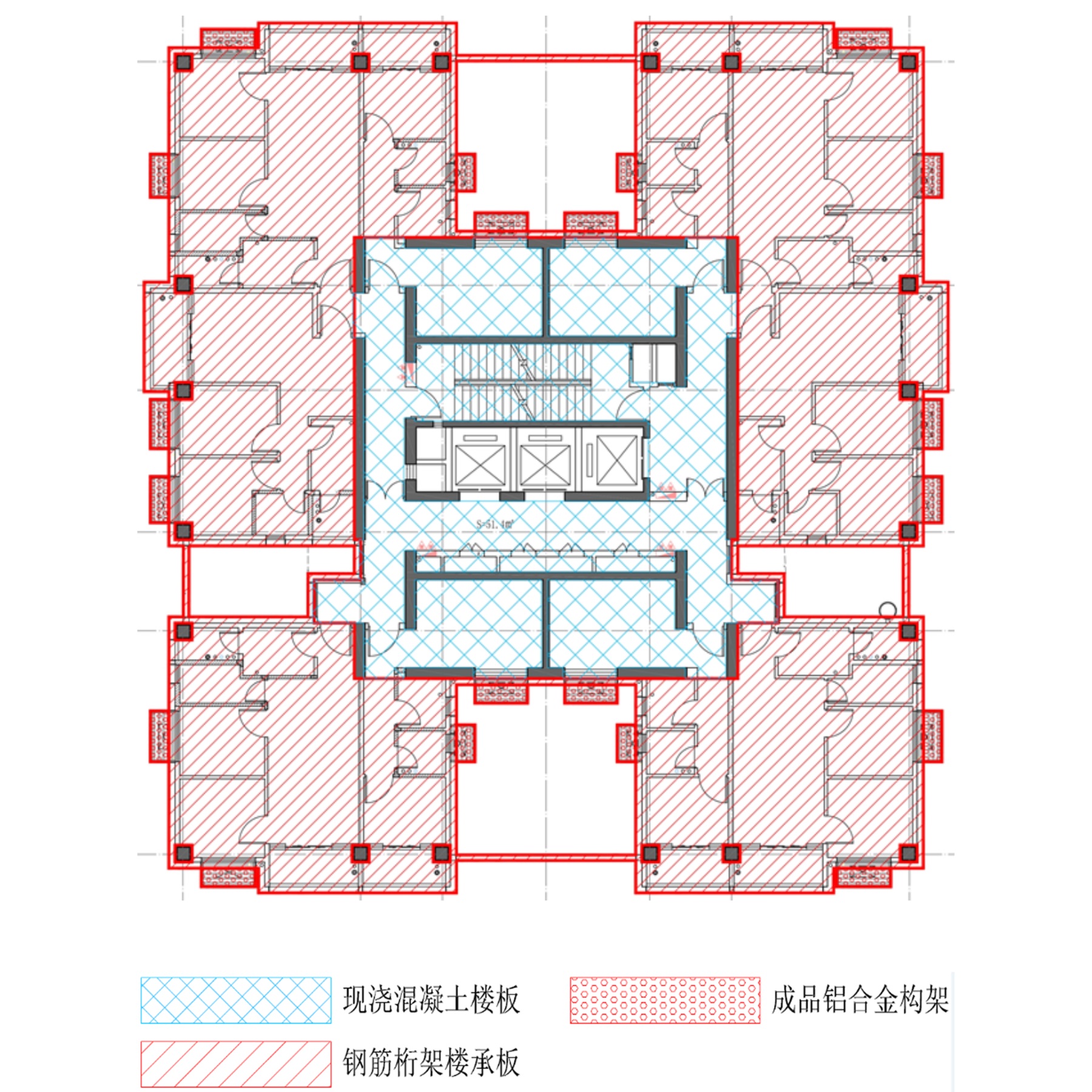

竖向结构构件采用钢管混凝土柱与铝模施工的现浇混凝土核心筒,混凝土核心筒可增强楼栋的舒适度与空间的实用性,钢管混凝土柱满足装配式需求。

The vertical structural components adopt steel-concrete columns and aluminum formwork for cast-in-situ concrete core, which enhances the comfort and practicality of the building's space. The steel-concrete columns also meet the requirements of prefabricated construction.

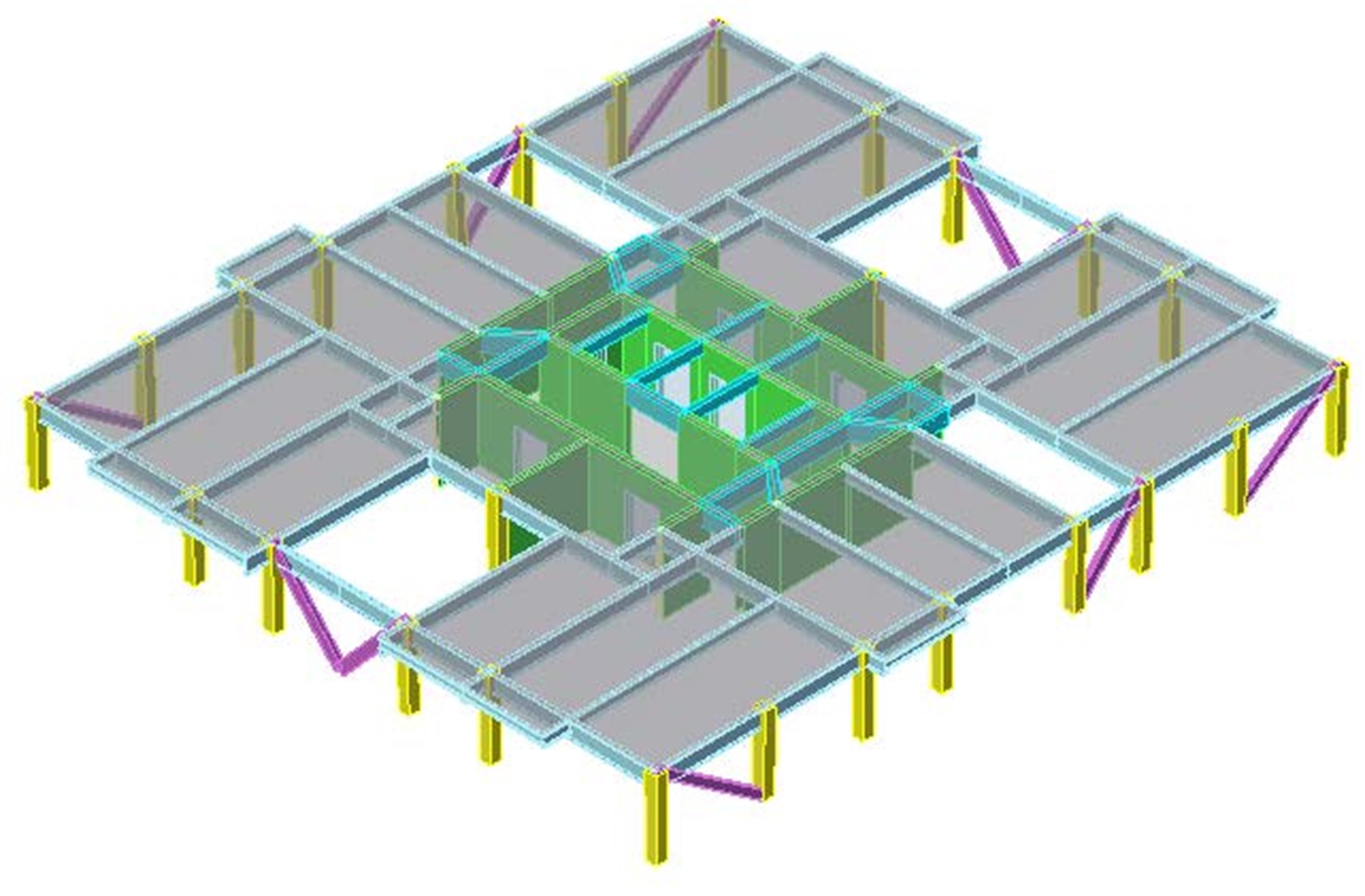

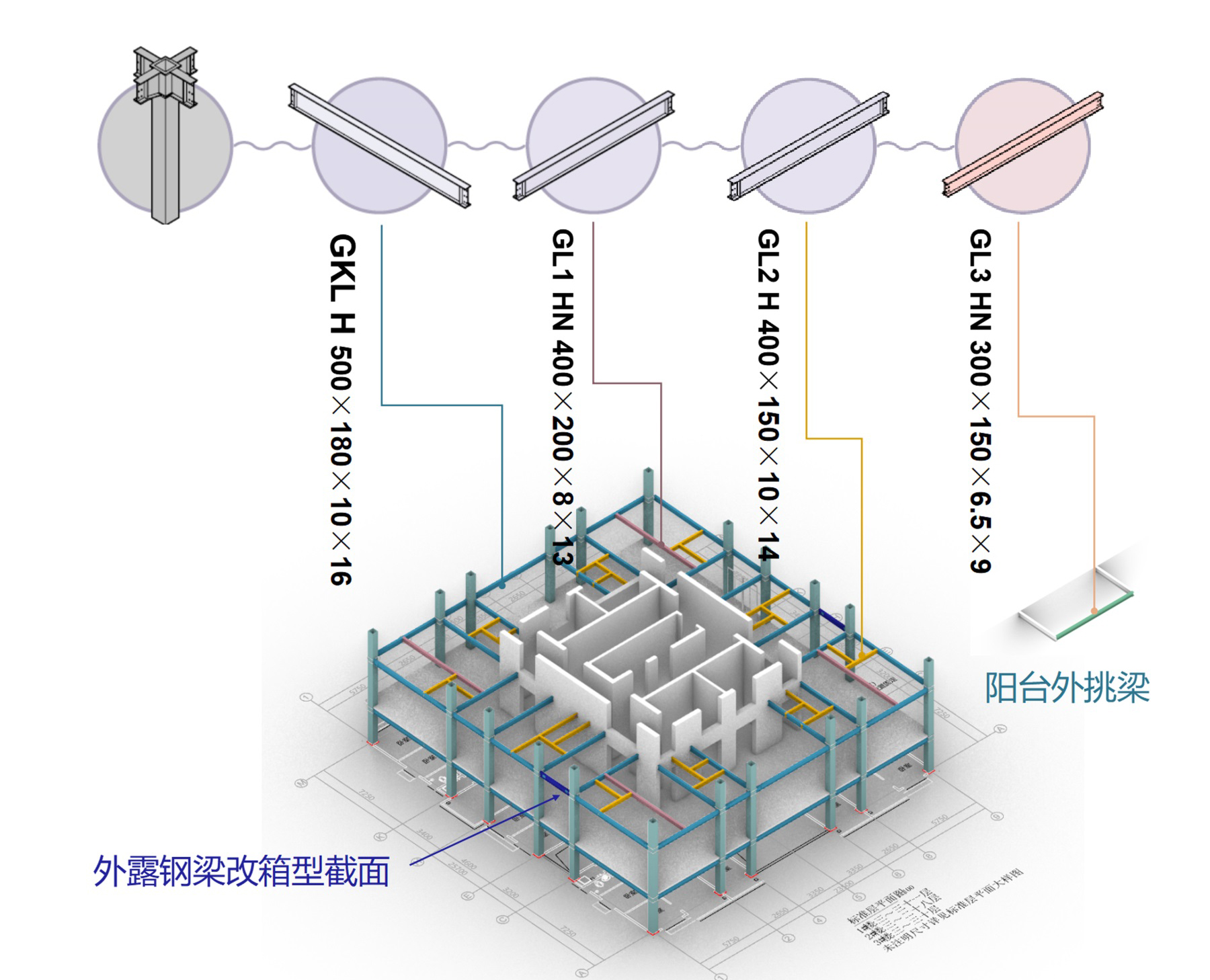

水平结构构件

Horizontal Structural Components

水平结构构件核心筒之外的梁全部采用钢梁,楼板和阳台板则是钢筋桁架楼承板,空调板使用预制铝合金构架。

All beams outside of the core tube for horizontal structural components are made of steel beams, while the floor slabs and balcony slabs are made of reinforced steel truss floor slabs, and the air conditioning slabs use prefabricated aluminum alloy frameworks.

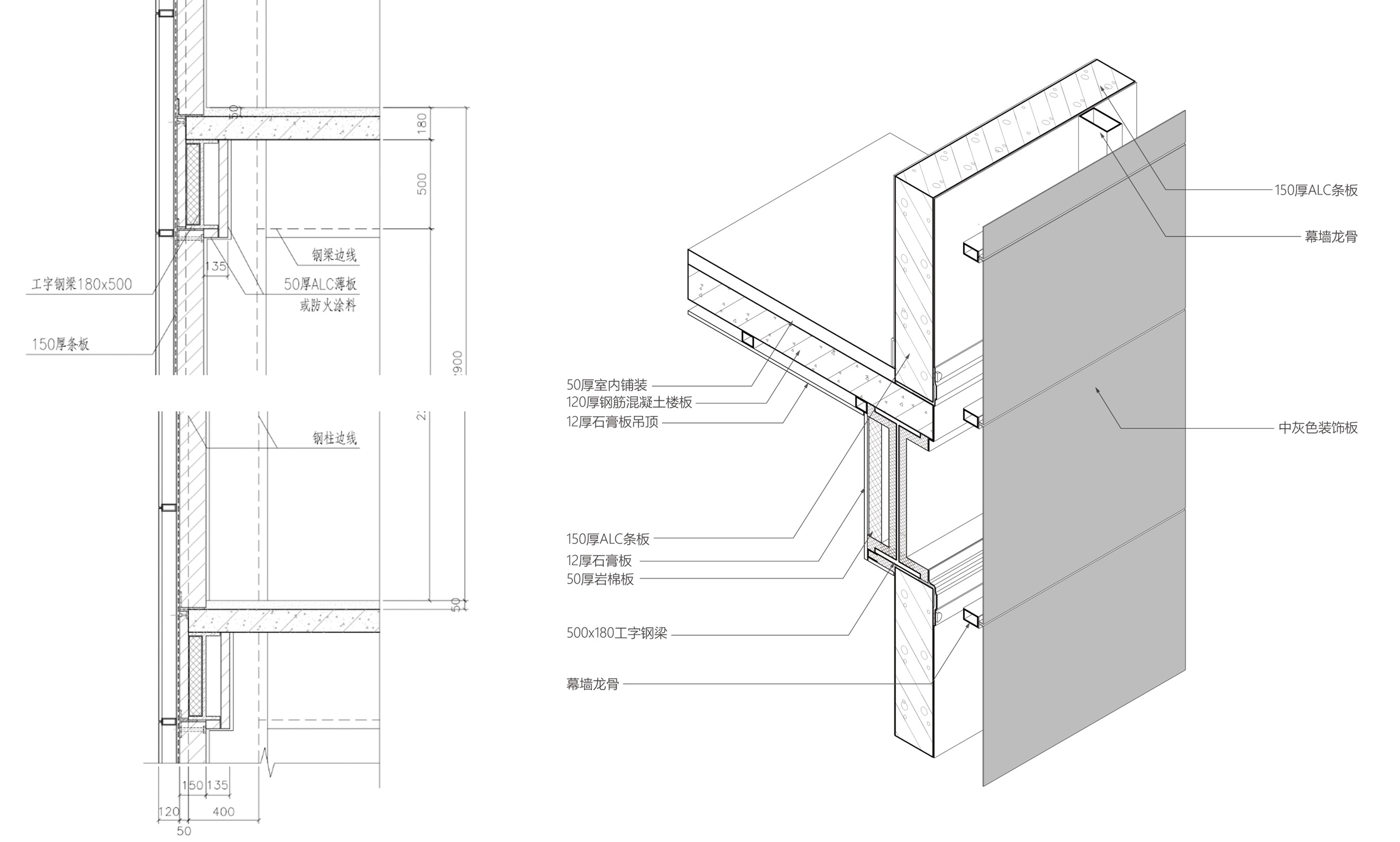

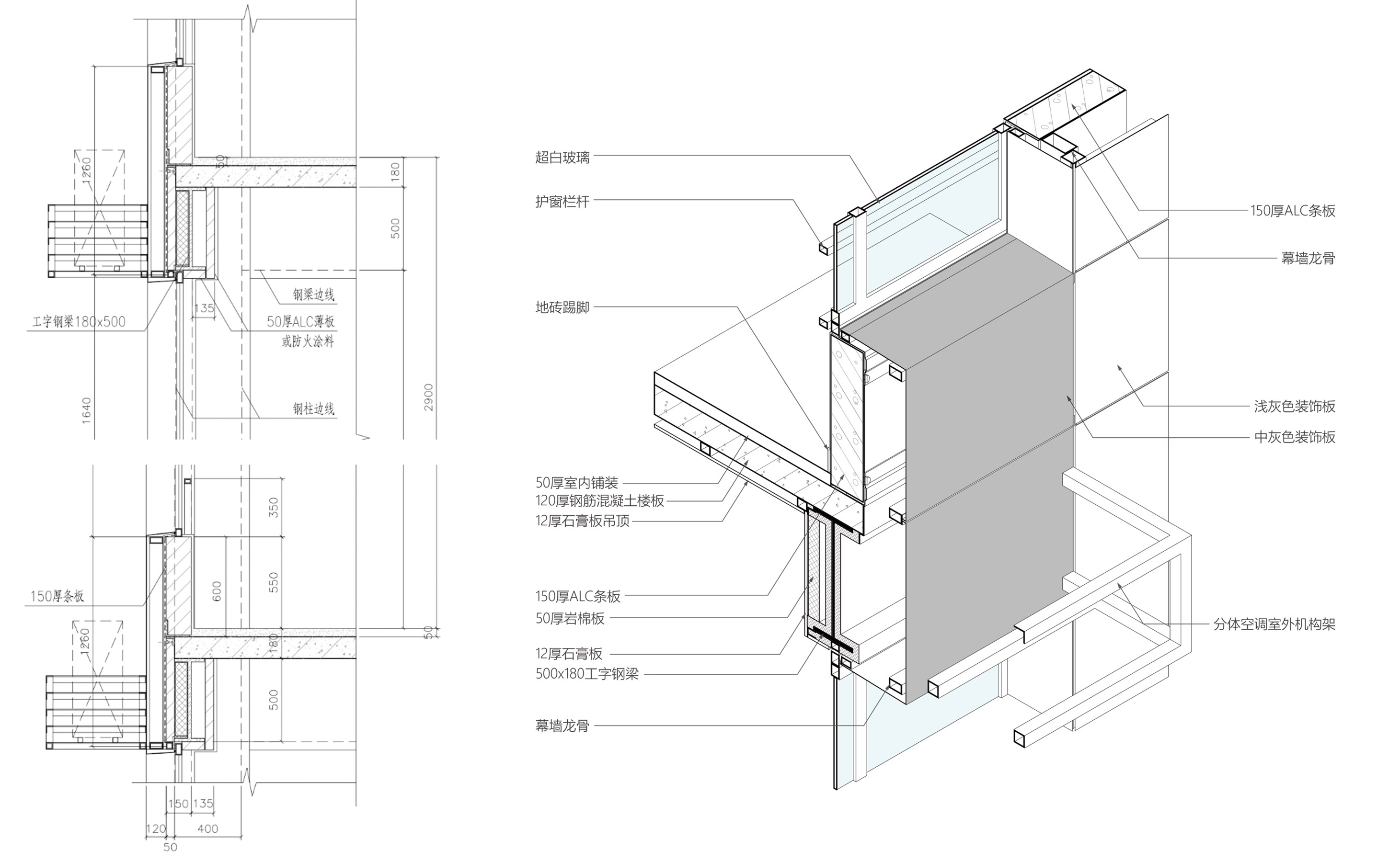

围护墙体系

enclosure wall system

围护墙选用了ALC条板+铝板幕墙+铝合金外门窗的做法,并与保温隔热装饰集成一体化设计。

The enclosure wall system adopts the approach of using Autoclaved Lightweight Concrete (ALC) panels, aluminum curtain wall, and aluminum alloy doors and windows, integrated with thermal insulation and decorative finishes.

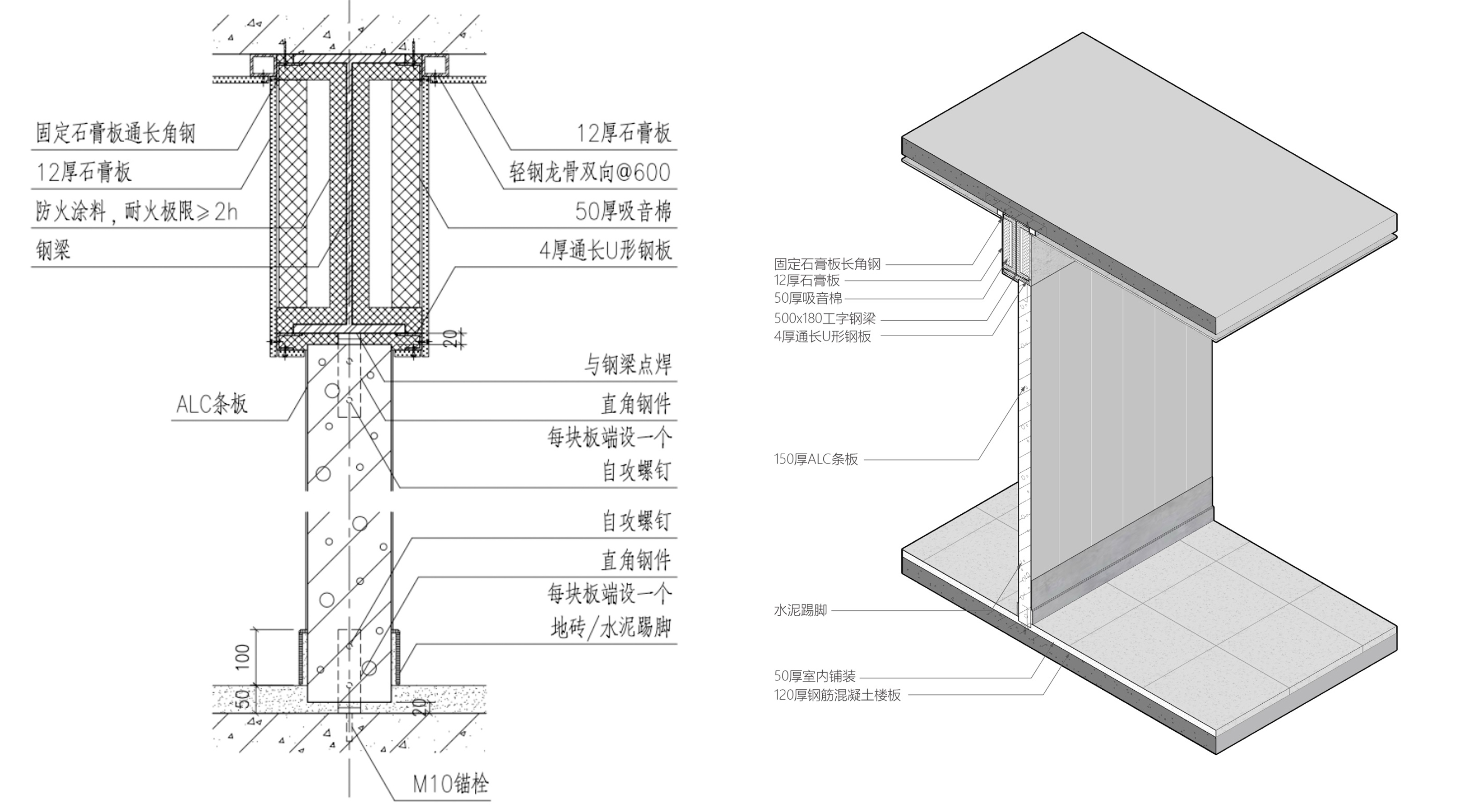

内隔墙体系

nternal partition wall system

内隔墙体系在分户墙与户内隔墙使用ALC条板或加气混凝土砌块墙,卫生间与核心筒内的管井楼梯间采用加气混凝土砌块砌筑。

The interior partition wall system uses ALC panels or aerated concrete blocks for partition walls between units, and aerated concrete blocks for bathrooms, pipe shafts, and stairwells inside the core.

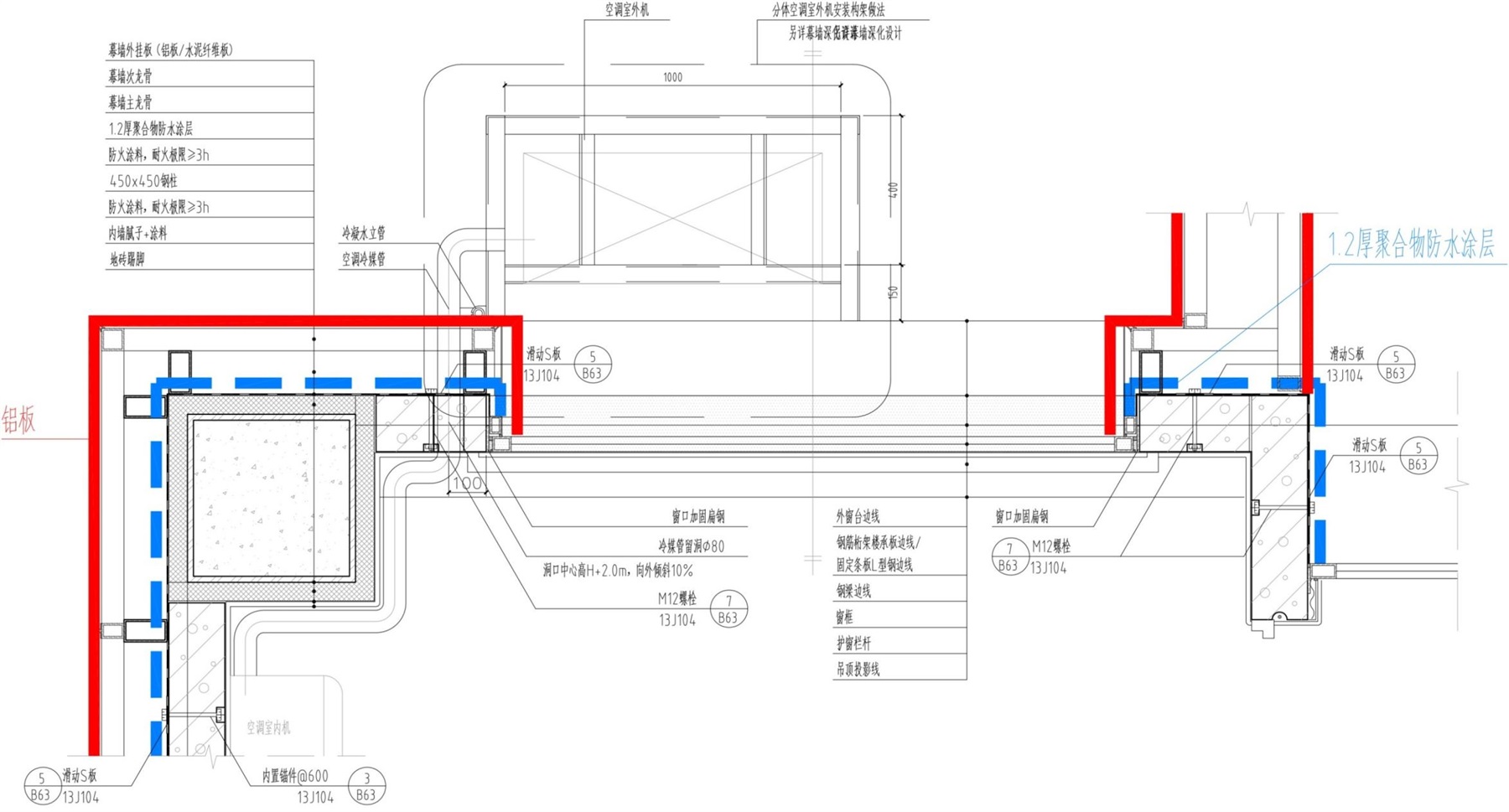

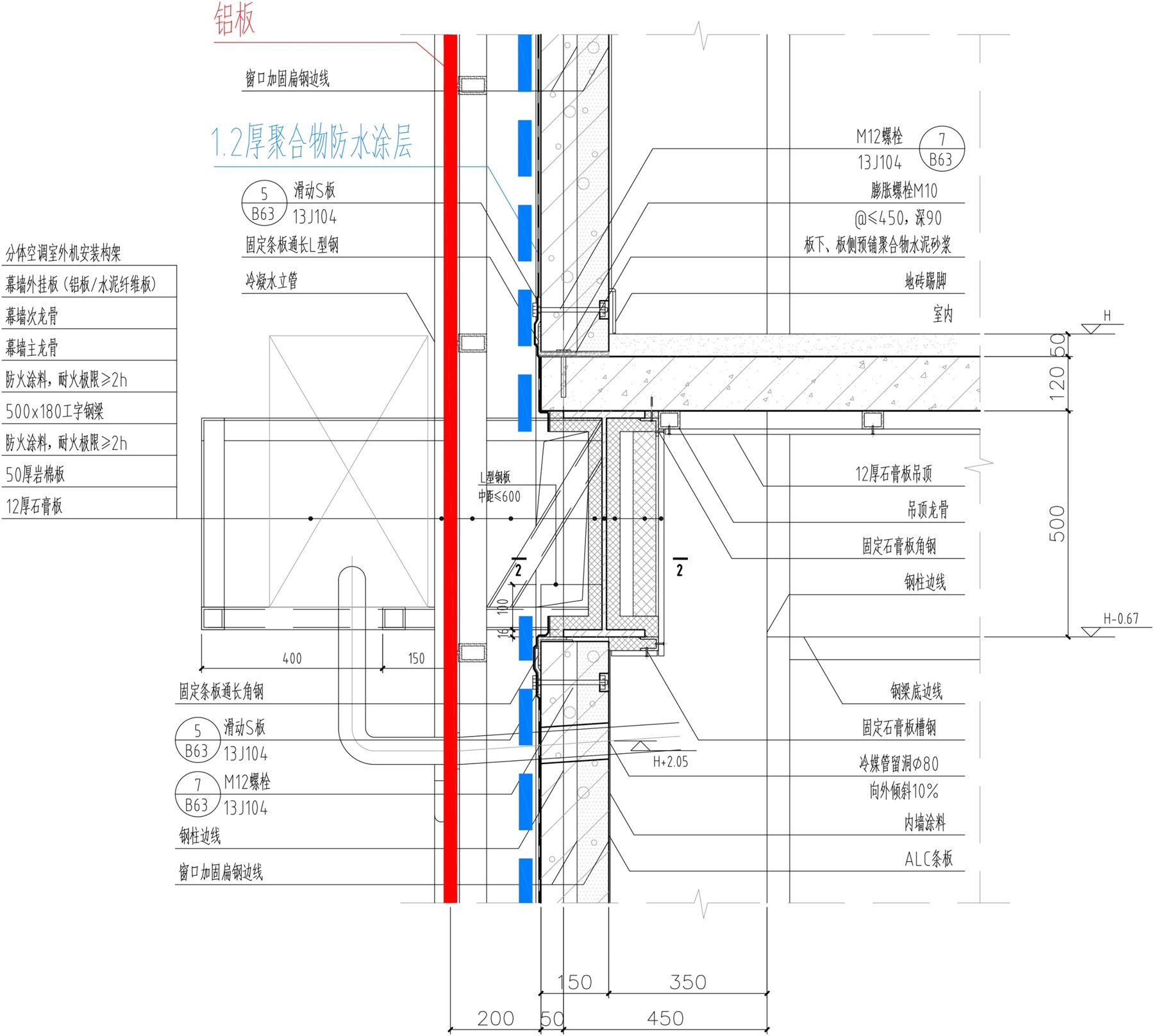

外墙防水

exterior wall waterproofing

我们在建筑外墙防水设计方面,采用了两道防水体系和空腔相结合的防水措施。使用密封铝板作为第一道外墙防水层,其次采用了1.2毫米厚的聚合物防水涂层作为第二道防水层,用于保护墙板外墙面。铝板与ALC墙板之间的空腔被利用为隔水层,更好地隔离墙体与雨水的接触,多重防水设计措施有效地防止渗透和漏水的发生。

For our building's exterior waterproofing design, we have adopted a double waterproofing system combined with an air gap. We use sealed aluminum panels as the first layer of exterior waterproofing, followed by a 1.2mm thick polymer waterproof coating as the second layer, which is used to protect the wall panels. The air gap between the aluminum panels and ALC wall panels is utilized as a waterproof barrier to better isolate the wall from rainwater. These multiple waterproofing measures effectively prevent penetration and leakage.

标准化平面与户型

Standardized floor plans and unit types

各层平面标准化,平面规整,承重墙上下贯通,形体上没有过大凹凸变化,符合建筑功能和结构抗震安全要求。各楼栋利用标准户型进行组合、拼接,以实现户型标准化。

Each floor plan is standardized, with a regular layout and load-bearing walls that connect from top to bottom. The building form has no significant irregularities and meets both functional and seismic safety requirements. Each building is constructed by combining and assembling standard unit types, achieving standardized unit layouts.

模数标准化与装配式建筑体系相协调

Modular standardization is in coordination with the prefabricated building system

建筑设计采用统一模数协调尺寸,符合现行国家标准《建筑模数协调标准》GB/T50002-2013的要求;套型采用模块化设计,起居室和卧室的开间采用模数设计, 厨房、卫生间采用模块化设计。墙板结合条板600毫米宽模数,设置开窗位置;门窗洞高度一致,同类房间宽度规格保持一致;窗户分格、开启扇宽度保持一致。

The building design adopts a unified module coordination dimension, which complies with the current national standard "Building Module Coordination Standard" GB/T50002-2013. The layout adopts a modular design, with the living room and bedroom's span designed according to the module, and the kitchen and bathroom designed according to modules. The wall panels are combined with a 600mm width module of the ALC panels, and window openings are set at appropriate positions. The height of door and window openings is consistent, and the width of the same type of room is consistent. The window gridding and opening width are also consistent.

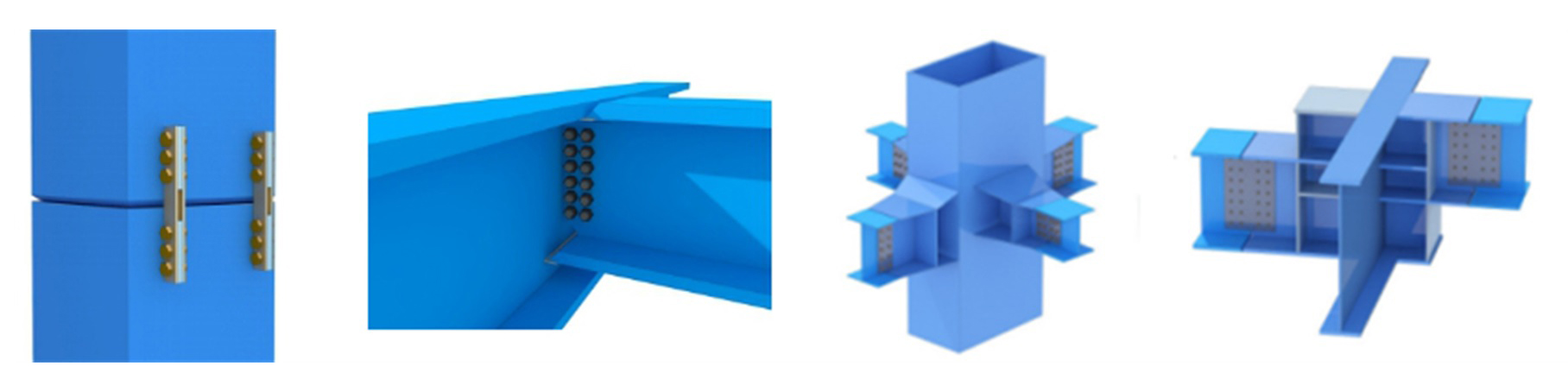

构件与构件连接节点标准化

Standardization of component-to-component connection nodes

我们在不同户型、不同部位之间,应用标准化的预制构件,如钢柱、钢梁、成品墙板、空调板等,最大限度地实现预制构件标准化。预制构件连接节点标准化,实现后期安装做法统一。

In different house types and locations, standardized prefabricated components such as steel columns, steel beams, precast wall panels, and air conditioning panels are used to achieve maximum standardization of prefabricated components. The connection nodes of prefabricated components are standardized to achieve uniform installation methods in the later stage.

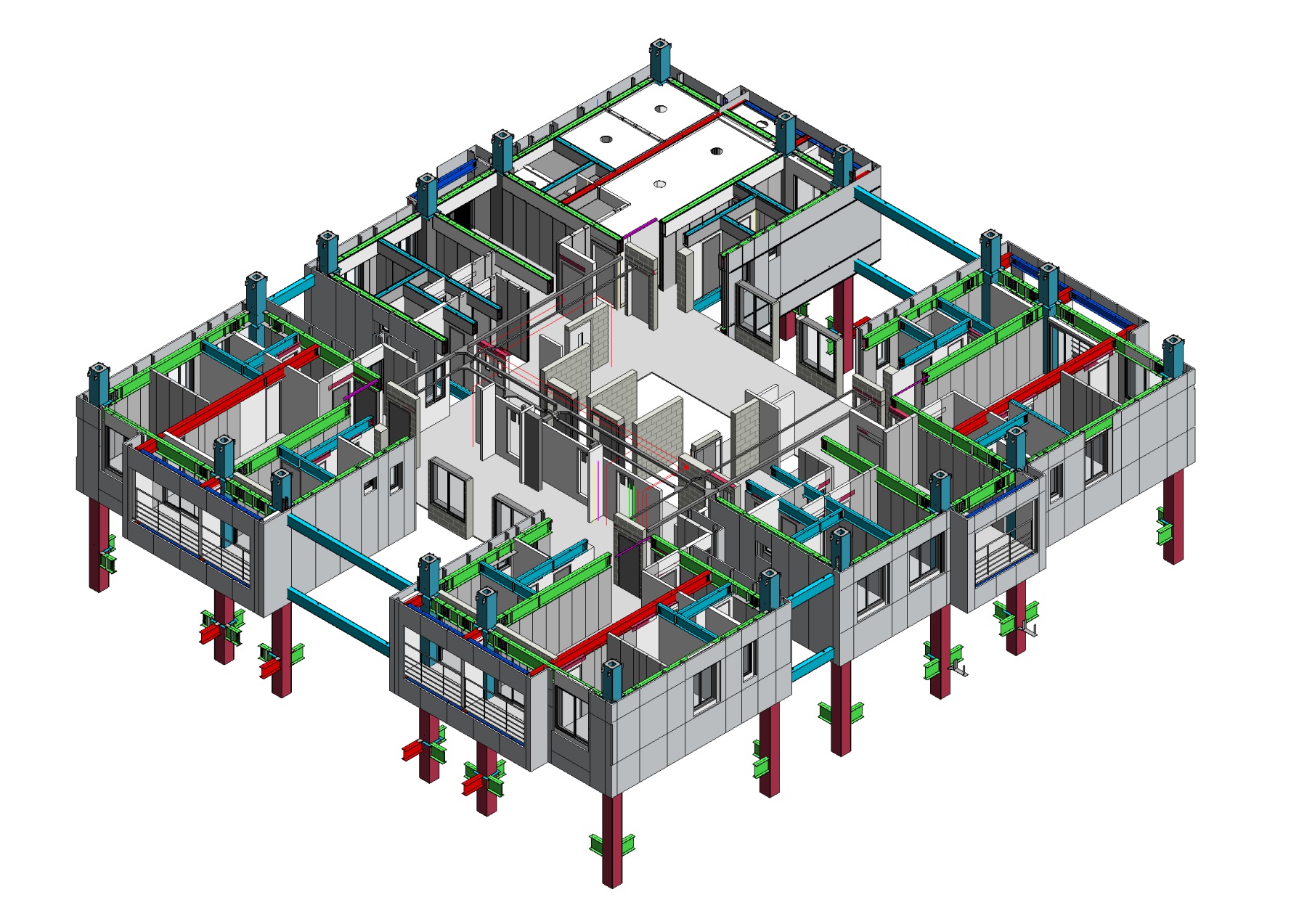

BIM应用

BIM application

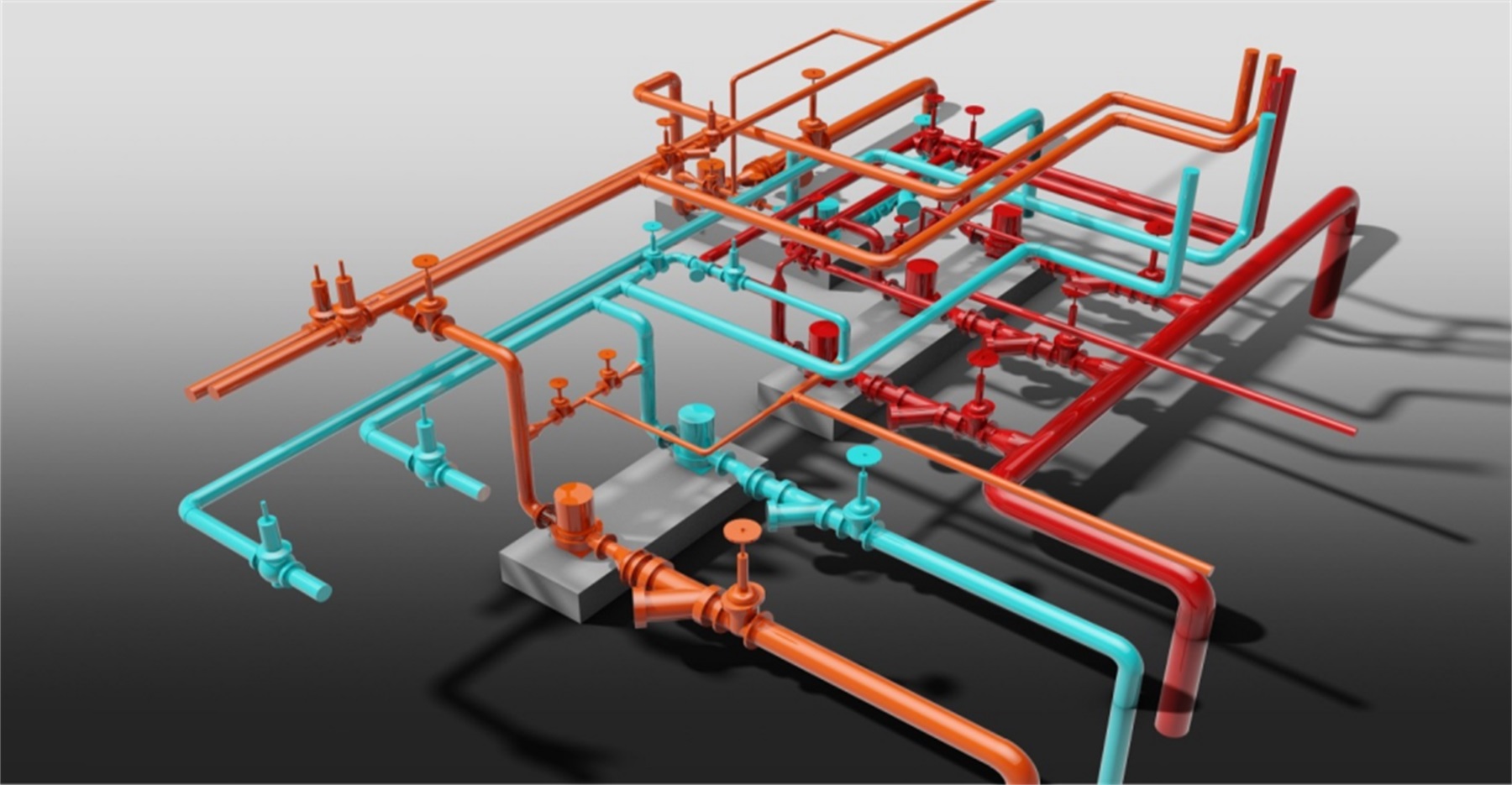

本项目BIM技术主要应用于钢结构安装、装配式设计、管线碰撞检测等内容。设计中制定 BIM 实施方案,按照BIM实施方案开展BIM应用;创建与施工范围一致的深化设计模型、施工模型、竣工模型;利用深化设计模型、施工模型开展BIM应用,模拟施工方案、优化施工方案、施工方案交底;利用模型与其他相邻工程开展协同,消除碰撞、合理划分施工界面;根据设计变更图纸更新施工模型。

The BIM technology in this project is mainly applied to steel structure installation, prefabricated design, and pipeline clash detection. A BIM implementation plan was developed in the design phase and BIM applications were carried out according to the plan. Deep design models, construction models, and completion models were created to match the scope of construction. BIM applications were carried out using the deep design models and construction models to simulate and optimize construction schemes, and for construction coordination. Collaboration with adjacent projects was carried out using the model to eliminate conflicts and rationally allocate construction interfaces. The construction model was updated according to the design change drawings.

深化设计阶段,我们进行钢结构深化与预制拼装,对钢构件施工过程进行模拟,利用BIM模型对杆件、节点连接、螺栓、焊缝进行预制拼装,辅助下料;展开碰撞检查与净空分析,预留洞口核查,并根据BIM模型进行各专业的深化设计。

During the detailed design phase, the steel structure is deepened and prefabricated for assembly. The construction process of the steel components is simulated, and the BIM model is used for prefabrication and assembly of bars, node connections, bolts, and welds to assist in material cutting. Collision checks and clearance analyses are performed, and openings are checked and reserved, and various professional designs are carried out based on the BIM model.

施工过程中我们借助BIM进行施工场地布置、进度控制、造价管理、施工方案模拟、施工工艺模拟、施工指导、材料控制及优化、装配式机房、无人机应用、VR技术应用等工作。

During the construction process, BIM is used for site layout, progress control, cost management, simulation of construction plans and processes, construction guidance, material control and optimization, prefabricated machine rooms, drone applications, VR technology applications, and other tasks.

结构指标监测

Structural Performance Monitoring

在结构指标的监测方面,通过对高层钢结构住宅风振加速度等指标的监测,填补国内该领域的空白;并将通过数值模拟、风洞试验、结构监测三项数据的交叉对比,指导后续钢结构住宅结构设计定案和优化。结构健康监测系统采用云端监测平台,通过远程指令将现场传感器采集的数据发送到云平台上进行分析、预警、评估。

In terms of monitoring structural indicators, the wind-induced acceleration of high-rise steel residential buildings will be monitored to fill the domestic gap in this field. The numerical simulation, wind tunnel test, and structural monitoring data will be cross-compared to guide the subsequent steel residential structure design and optimization. The structural health monitoring system adopts a cloud-based monitoring platform, which sends the data collected by on-site sensors to the cloud platform for analysis, warning, and evaluation through remote instructions.

绿色建造

Green construction

钢结构建材与装配式建造,结合BIM技术,可实现绿色建材绿色施工。与传统建造相比,此模式可减少建造用水80%,减少材料浪费20%,减少建造垃圾80%,综合节能70%,降低建筑后续维护费用95%,钢结构材料100%可回收或降解。

The use of steel structure building materials and prefabricated construction, combined with BIM technology, enables green materials and construction practices. Compared to traditional construction, it reduces water usage by 80%, material waste by 20%, construction waste by 80%, and achieves an overall energy saving of 70%. It also reduces building maintenance costs by 95%, and allows for 100% recyclable or degradable steel structure materials.

室内空间实景 ▽

设计图纸 ▽

完整项目信息

项目名称:适应标准化钢结构体系下的居住产品类型——湛江市东盛路南侧钢结构装配式公共租赁住房

项目类型:住宅建筑

项目地点:广东省湛江市赤坎区东盛路南侧

EPC单位:中建科工集团有限公司

设计单位:深圳大学建筑设计研究院元本体工作室

主创建筑师:蔡瑞定、马越

建筑团队:蔡瑞定、马越、姚远、李程、陈恒生、陈景文、何伟勇。

业主:湛江市住房和城乡建设局

设计时间:2019年4月—2019年12月

建设时间:2019年11月—2021年12月

用地面积:24885平方米

建筑面积:68606平方米

其他参与者:

结构:刘畅、张剑、徐斌、邱松明

给排水:李赫、侯健

电气:刘中平、严润锋

暖通:韩国园

造价:唐进

室内:立木设计研究室有限公司、中建科工集团有限公司、浙江亚厦装饰股份有限公司、深圳大学建筑设计研究院元本体工作室

景观:深圳地道国际设计顾问有限公司

摄影:吴清山、中建科工、立木设计

版权声明:本文由深圳大学建筑设计研究院元本体工作室授权发布。欢迎转发,禁止以有方编辑版本转载。

投稿邮箱:media@archiposition.com

上一篇:“自行车之城”阿姆斯特丹,开放世界首个水下自行车停车场

下一篇:以光为景:韦来摄影艺术空间 / 余留地