设计单位 斯图加特大学计算机设计与建造研究所、建筑结构与结构设计研究所

展出地点 意大利威尼斯“威双”军械库展场

装置面积 总面积125平方米

搭建时间 2021年

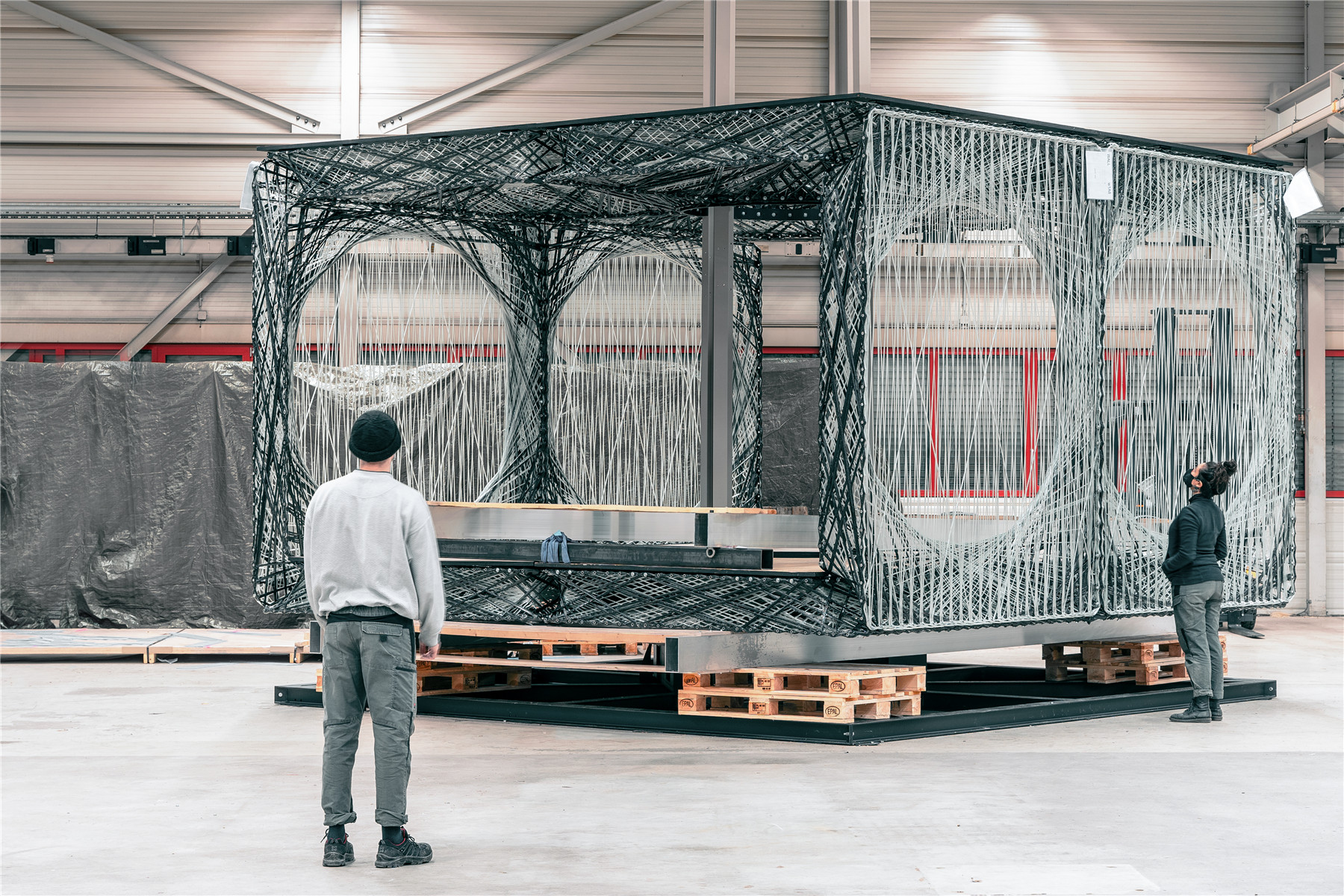

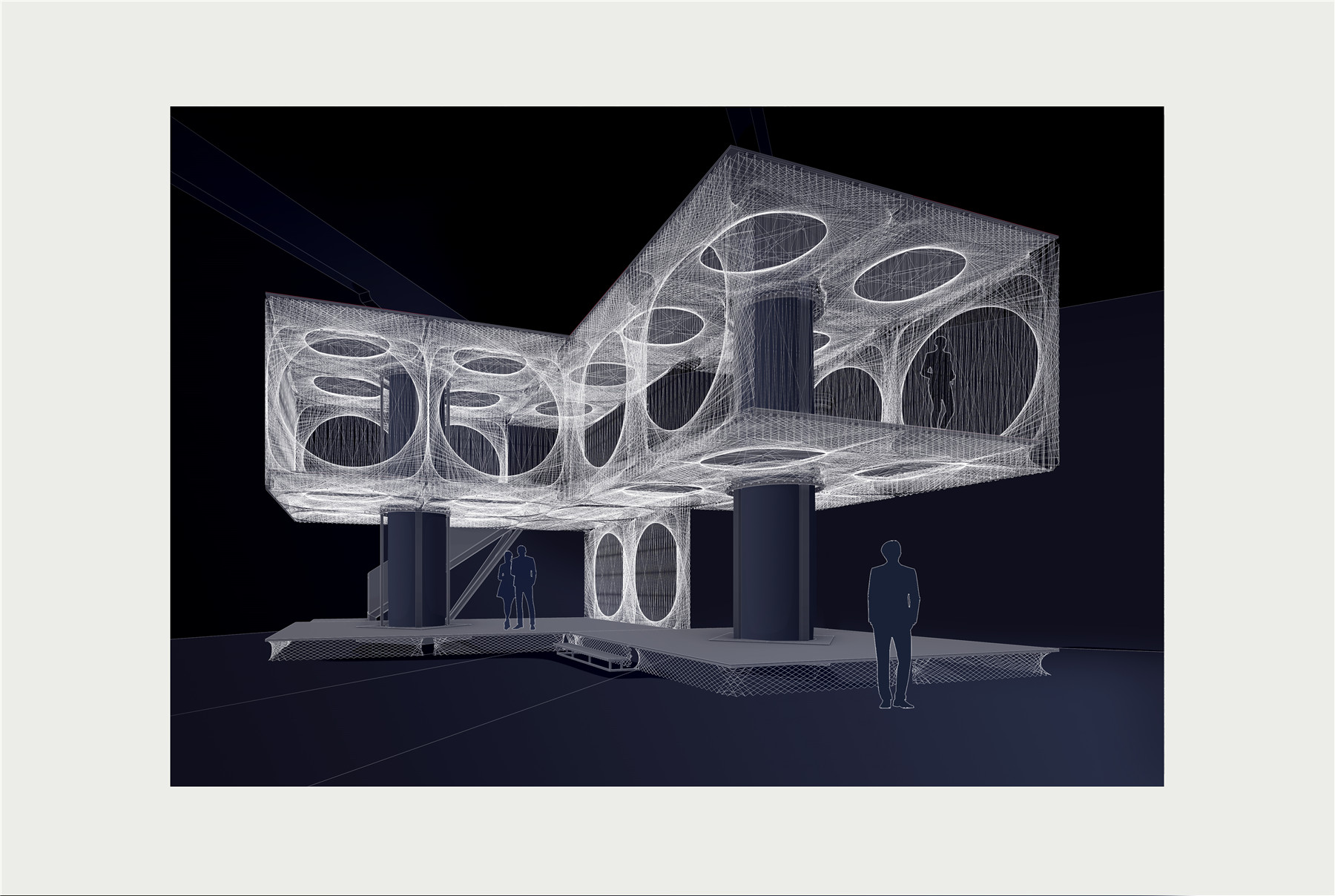

为了回应第17届威尼斯双年展主题“我们将如何共同生活?”,斯图加特大学的计算机设计与建造研究所(ICD)和建筑结构与结构设计研究所(ITKE)展示了一个完全由机器人制造的、由纤维作为建筑元素的全尺寸可居住装置——纤维屋(Maison Fibre),探索未来可居住空间的设计和建造的替代方法。这也是该种类下第一个多层建筑。

Maison Fibre, exhibited at the 17th International Architecture Exhibition – La Biennale di Venezia 2021, explores an alternative approach to the design and construction of future habitable spaces. In response to the exhibition theme “How will we live together?”, the Institute for Computational Design and Construction (ICD) and the Institute of Building Structures and Structural Design (ITKE) of the Cluster of Excellence IntCDC at the University of Stuttgart present a full-scale inhabitable installation made entirely from robotically produced, fibrous building elements, constituting the very first multi-story structure of its kind.

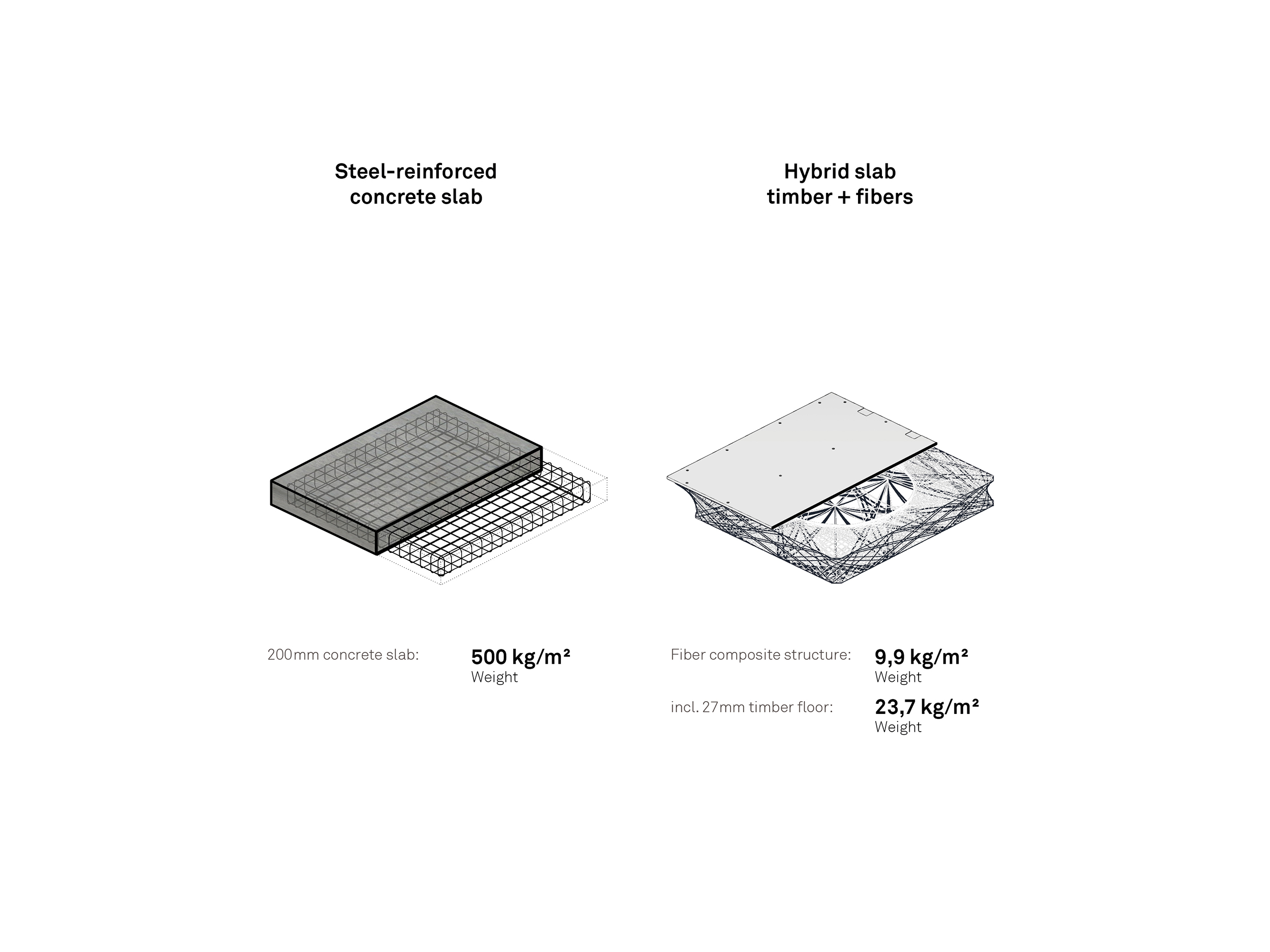

纤维屋为游客提供了强烈的材料体验,展示了未来的空间表达与高度非物质化的结构。每个建筑元件都可以由几公斤的当地建筑材料制成。相比20世纪建筑的榜样——柯布的多米诺住宅,纤维屋的重量为其五十分之一,指向了一种新的建筑物质文化,以及相关的生态(材料和能源)、经济(价值链和知识生产)、技术(数字技术和机器人)和社会文化事项。

Maison Fibre offers visitors the intense material experience and spatial expression of future, highly dematerialized structures, where each building element can be locally made from just a few kilos of construction material. Compared to Le Corbusier’s Maison Dom-Ino as a role model for 20th-century architecture, the weight footprint of Maison Fibre is reduced fiftyfold and points toward a novel material culture in architecture, as well as the related ecological (material and energy), economic (value chains and knowledge production), technical (digital technologies and robotics), and sociocultural matters entailed herein.

重新思考共同生活的物质基础

Rethinking the physical substrate for living together

建筑已成为物质强度和环境危害最大的人类活动之一。用于承重结构的建筑材料占建筑材料使用量的一半以上,其人均消耗量在上个世纪成倍增长。目前的建筑形式,优先考虑简单的施工过程,而不是节约材料和资源,这似乎不是可持续的。迫切需要新的方法。

Construction has become one of the most materially intense and environmentally detrimental human activities. The per capita consumption of construction materials for load-bearing structures alone, which account for more than half of the materials used in buildings, has multiplied over the last century. Building in the present form, which prioritizes simple construction processes over saving material and resources, no longer seems sustainable. New approaches are urgently needed.

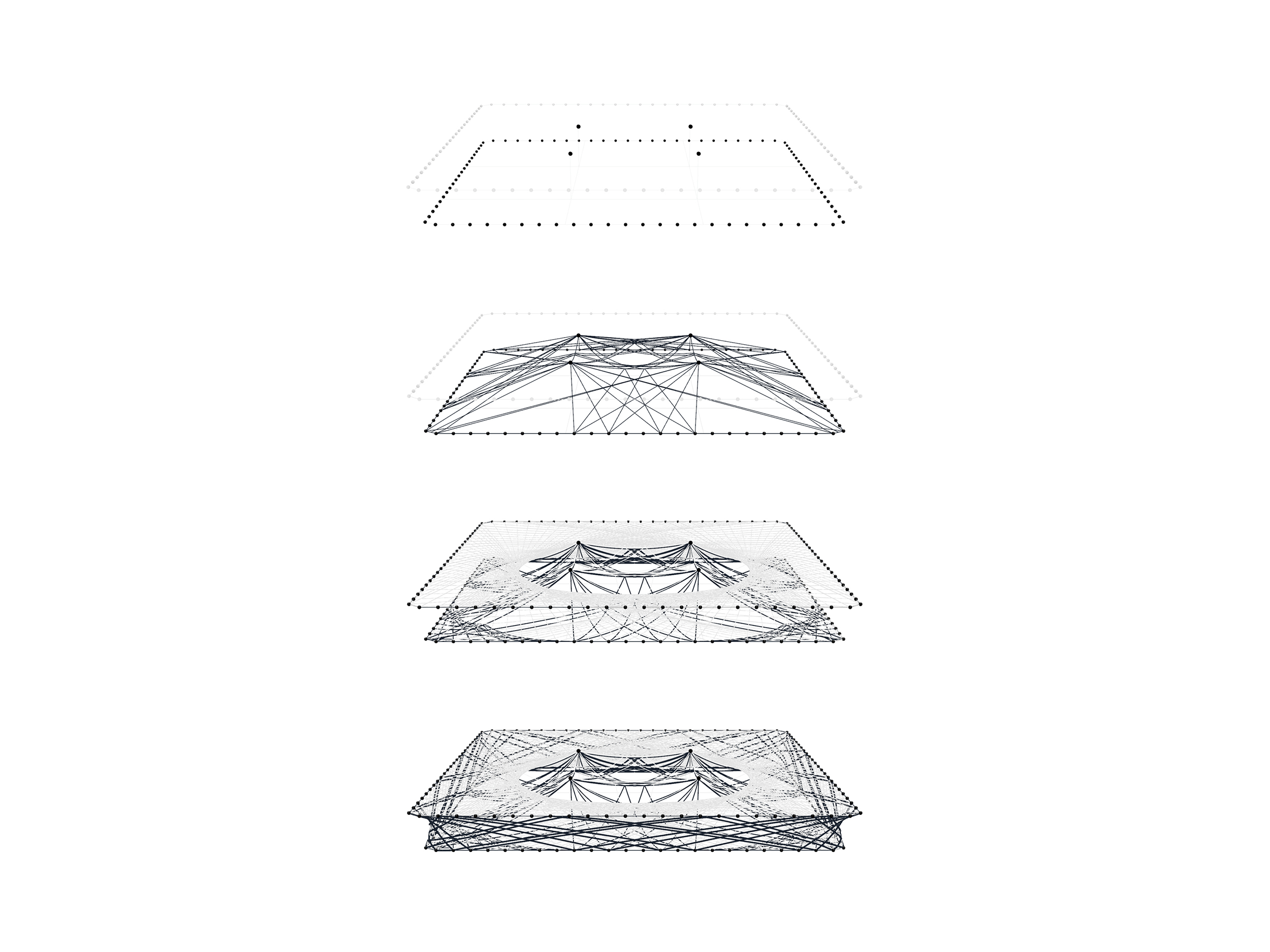

自然界提供了这样一个范例:在生物学中,几乎所有的承重结构都是纤维系统,纤维的组织、方向和密度都根据力进行精确校准。由此产生的高水平的形态分化、功能和相关资源效率是自然结构的象征。多年来,项目团队研究用“更少的材料”实现“更多的形式”的仿生原理。纤维结构为建造未来人类栖息地提供了一种截然不同的材料方法

Nature provides just such a paradigmatic alternative: Almost all load-bearing structures in biology are fibrous systems, in which the fiber organization, directionality, and density are finely calibrated with the occurring forces. The resulting high level of morphological differentiation, functionality, and related resource efficiency are emblematic of natural structures. The biomimetic principles of using “less material” by having “more form” have been investigated for many years by the project team at the University of Stuttgart. Fibrous construction offers a profoundly different material approach for building future human habitats.

纤维屋:走向一种去物质化的物质文化

Maison Fibre: Towards a material culture of dematerialisation

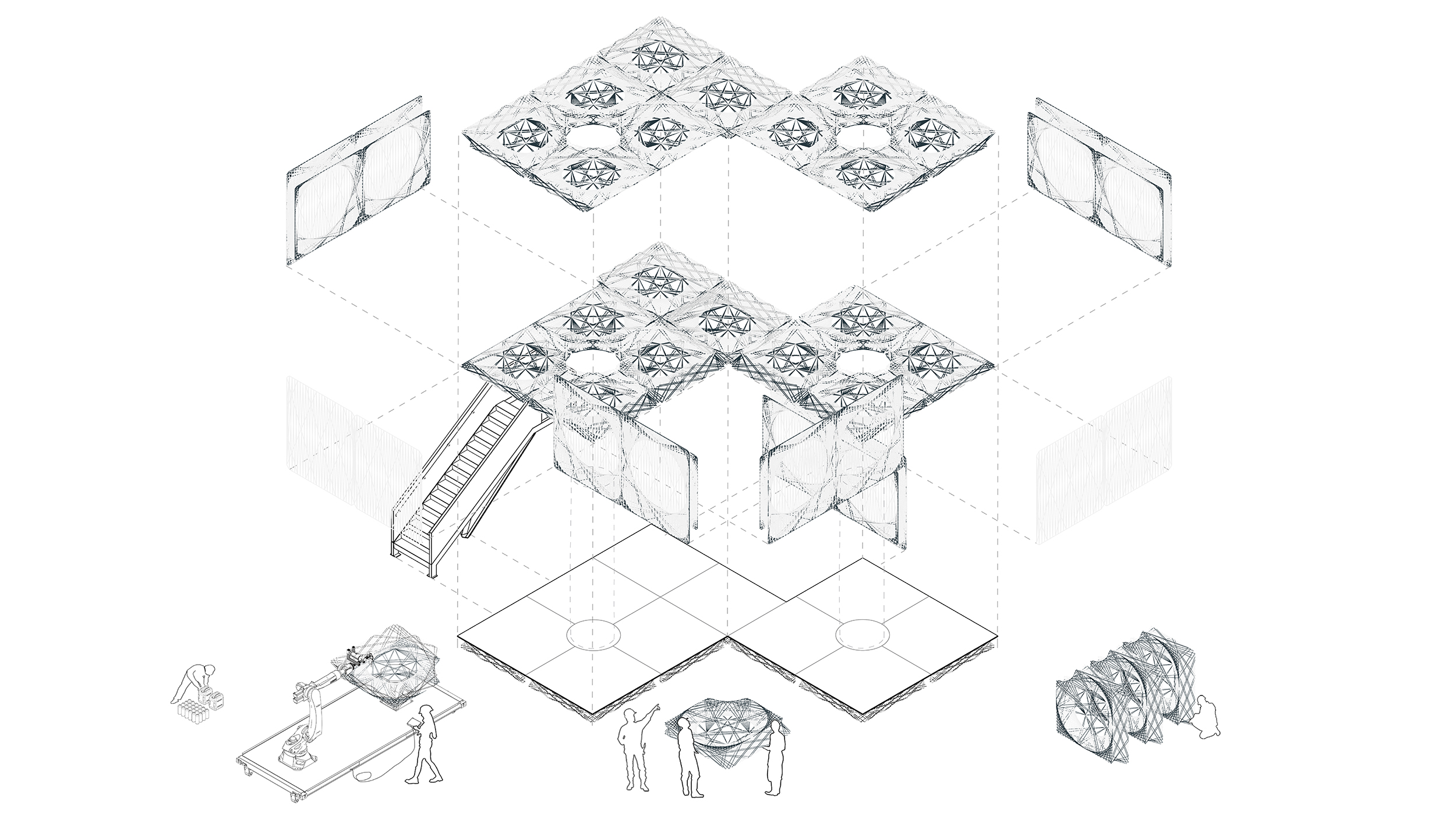

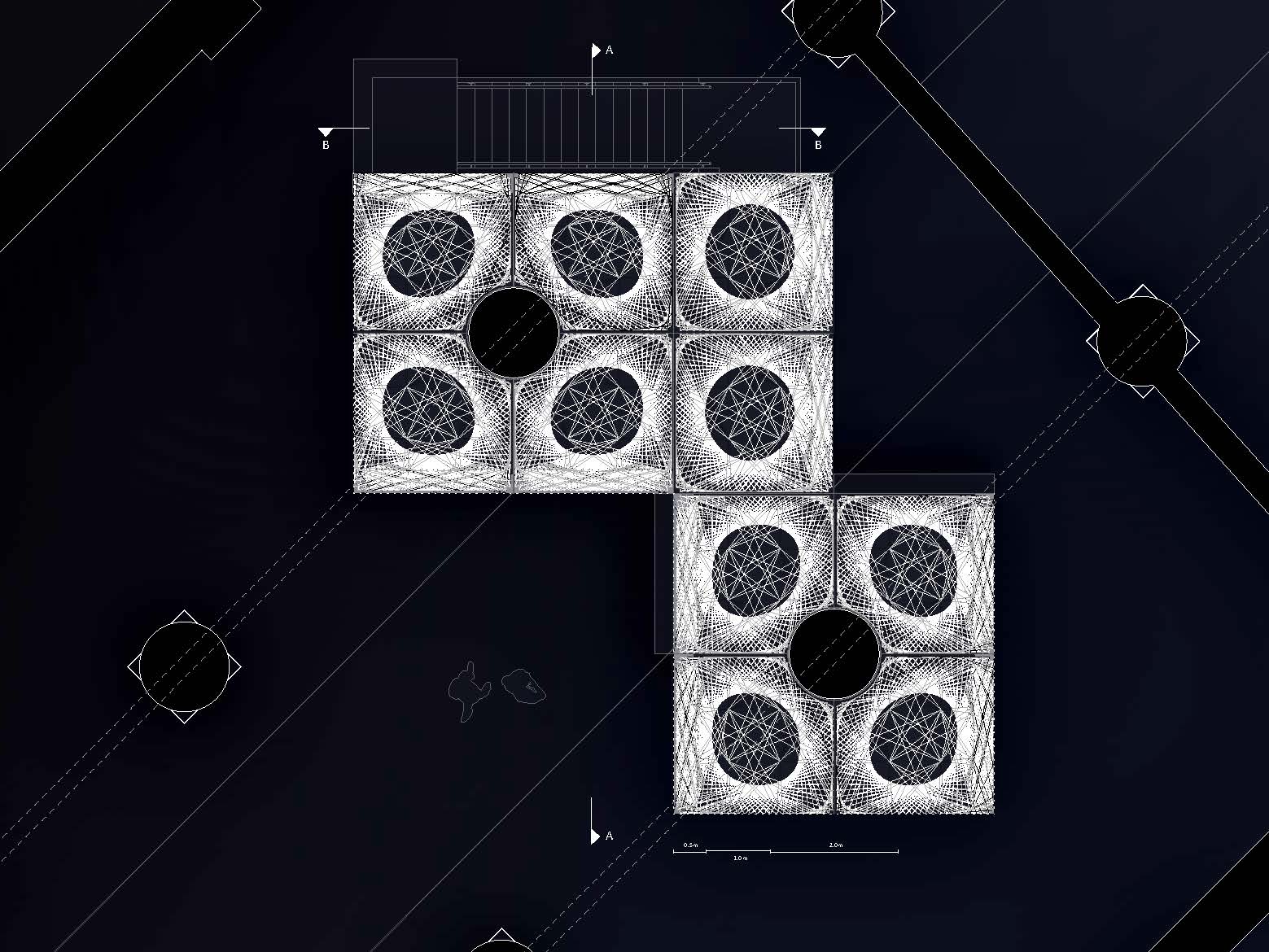

纤维屋整个结构完全由纤维粗纱组成,本质上是一束束无尽的、单向的纤维。为了突出其典型特征,该项目使用了一个基于2.5米网格尺寸的可重构墙体和天花板单元系统,这也是住宅中常见的单元尺度。

The entire structure consists exclusively of so-called fiber rovings, essentially bundles of endless, unidirectional fibers. To underline the model character of the project, a system of reconfigurable wall and ceiling elements based on the 2.5-meter grid dimension typical of residential buildings was developed.

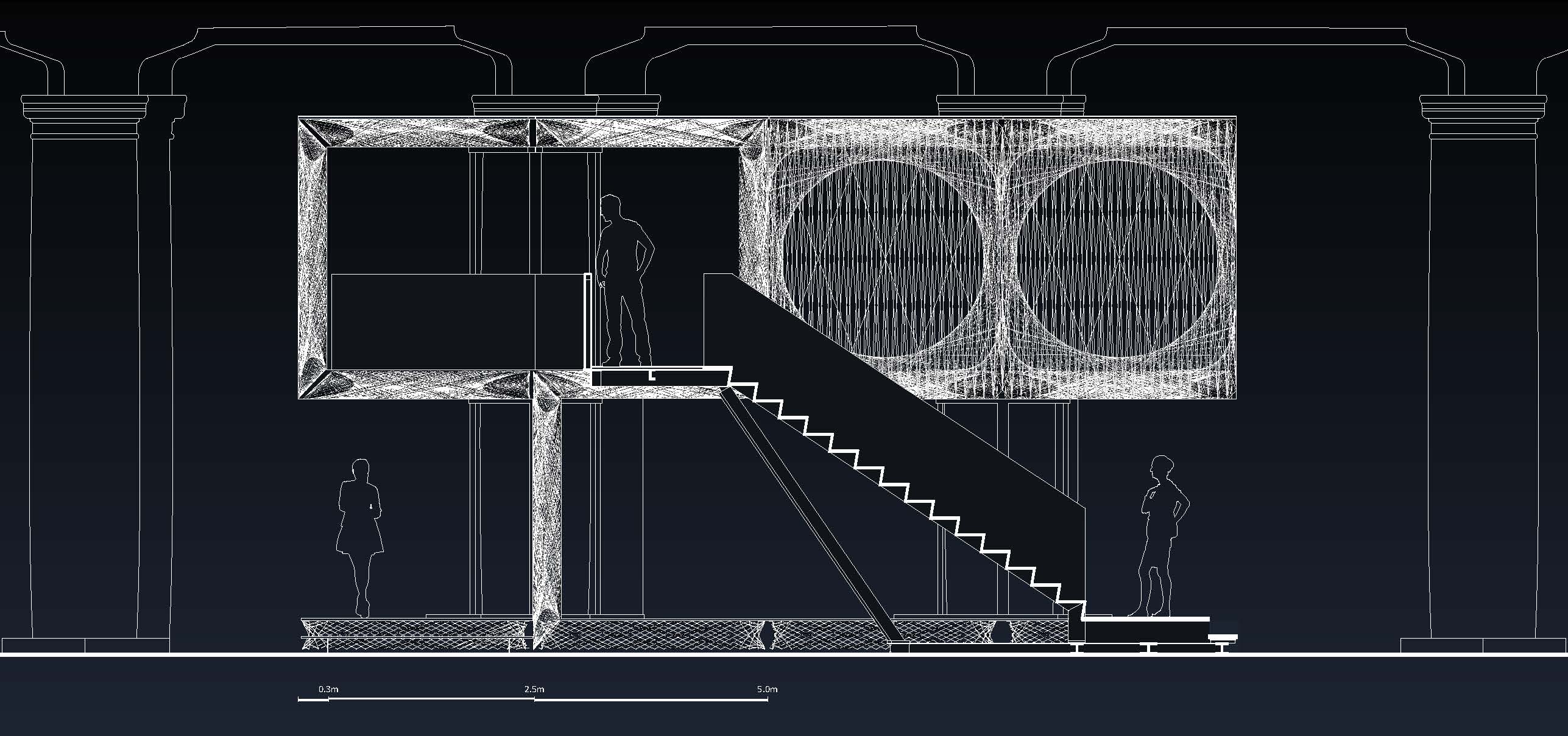

该项目也投射了对建筑历史造型的参考,如勒·柯布西耶的多米诺住宅。该装置的建筑面积、三层楼的划分和多功能、可扩展的系统都对其有所参考。与块状构造(tectonics of the massive)相比,纤维结构的本质是截然不同的,游客可以在空间和触觉上体验到。

The project's projective aspect is derived from its reference to a formative model of architectural history, Le Corbusier's Maison Dom-Ino. The floor area of the installation corresponds to the historical reference, as does the division over three floors and the versatile, expandable system. The radically different nature of the fibrous - compared to tectonics of the massive - can be experienced spatially and tactilely by the visitors.

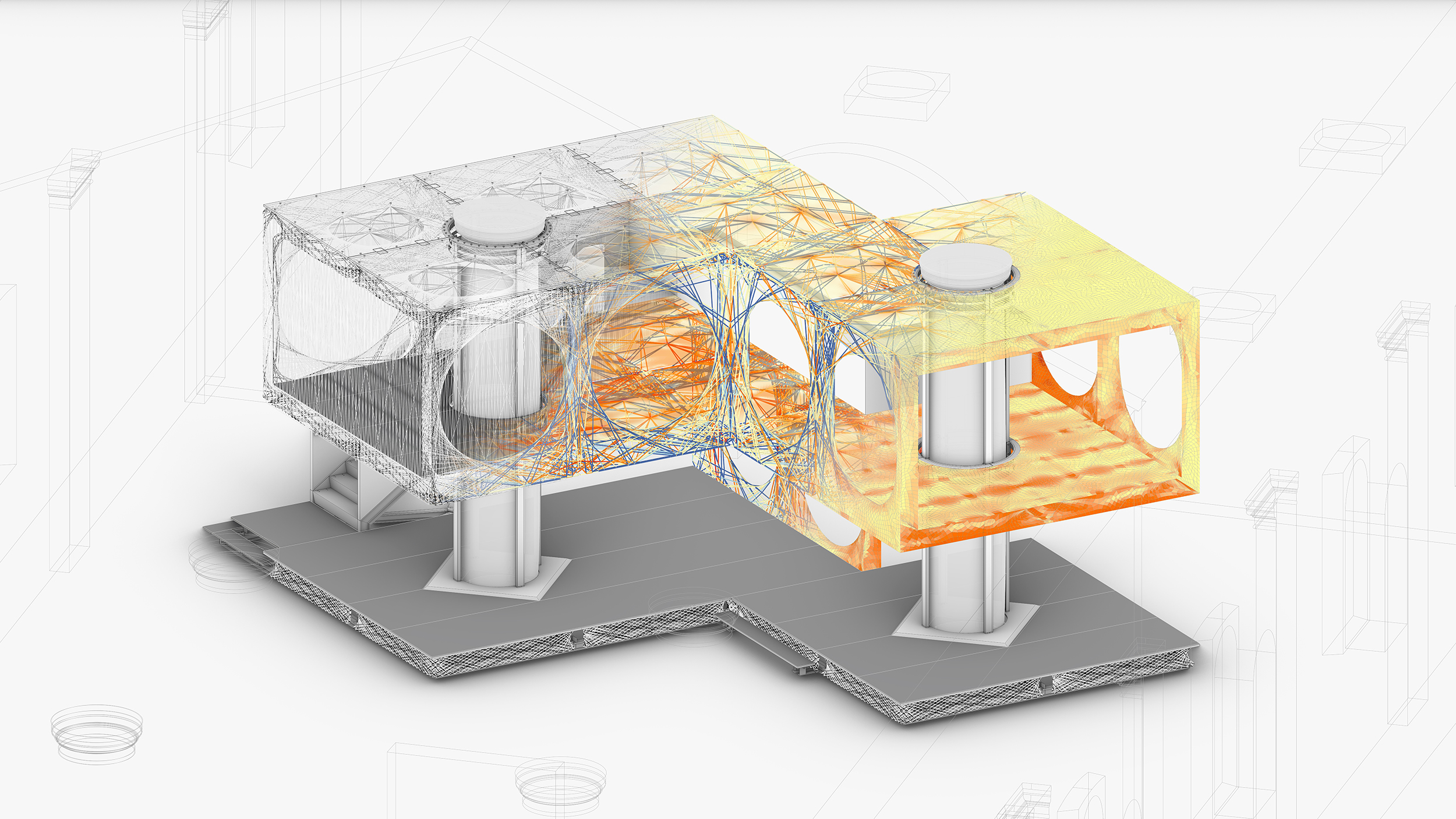

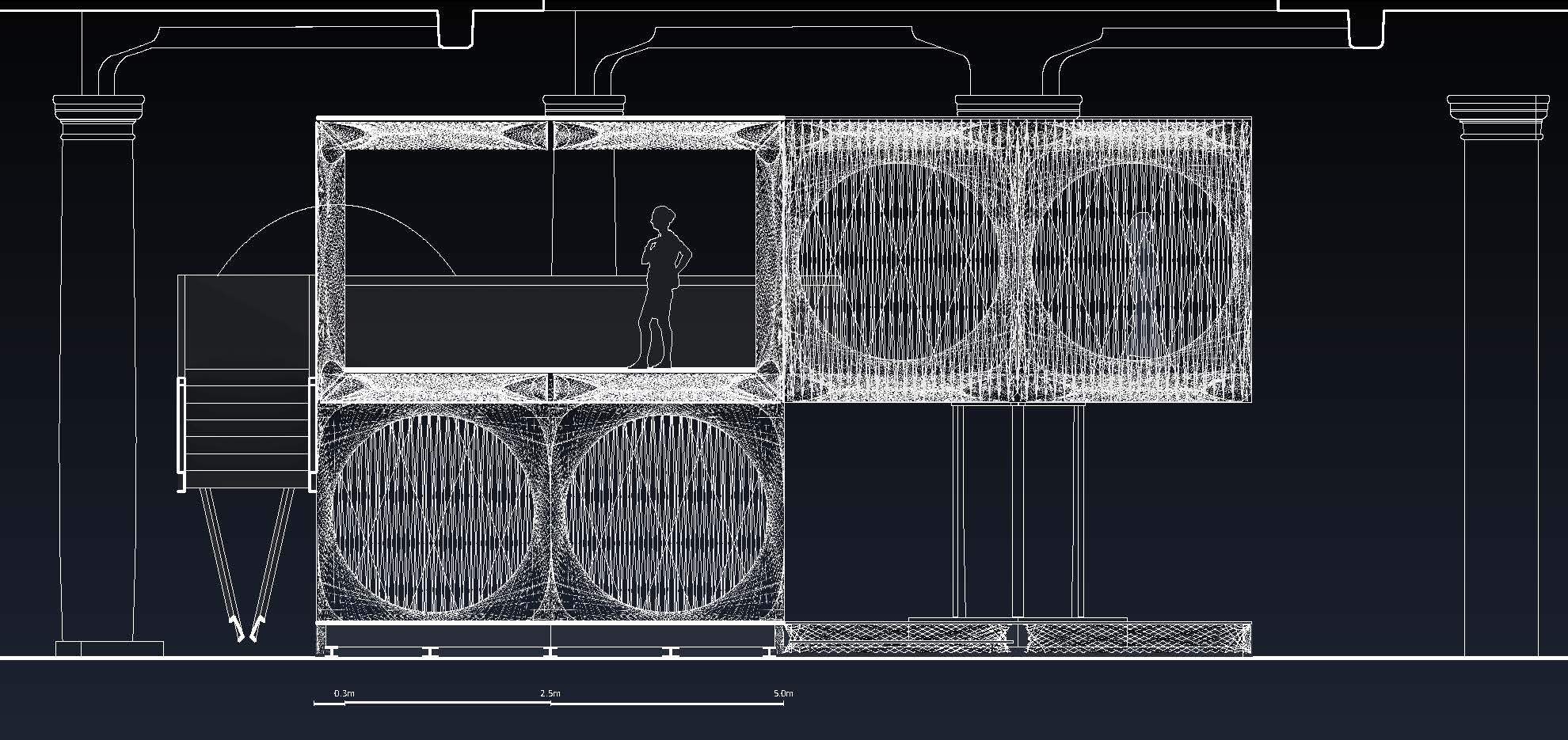

另一个关键的区别是适应性,及其与现有建筑的相互作用,这对未来城市建筑而言是决定性的。项目将军械库展厅的柱子整合到装置中,从而强调了这一点。

Another key difference is the possible adaptability and thus the interaction with the existing building stock, which will be decisive for future urban buildings. This is deliberately emphasized by integrating the existing columns of the Arsenale building into the installation.

纤维构造:适应性的物质化和多变的物质性

Fibrous Tectonics: Adaptable materialization and variable materiality

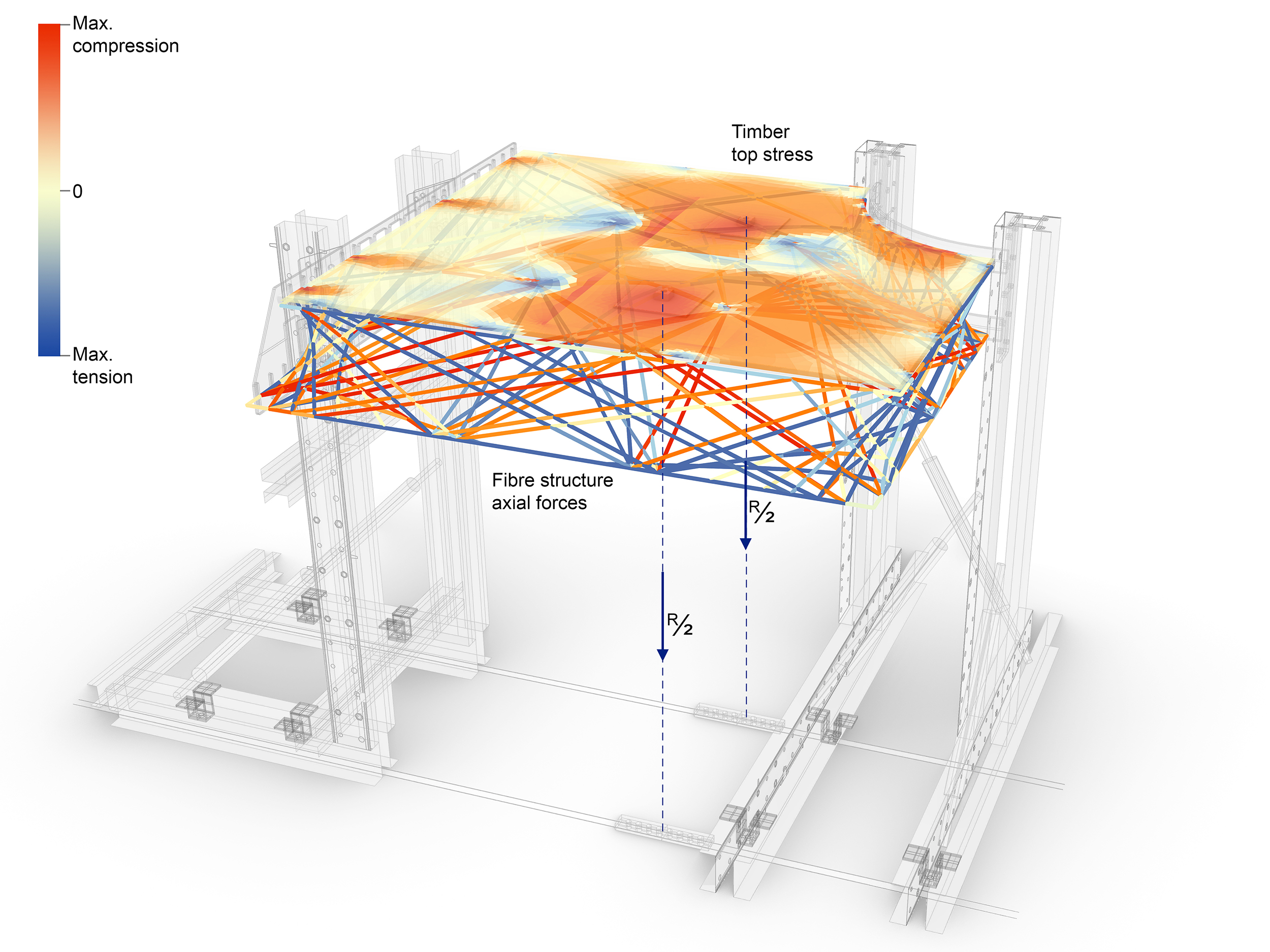

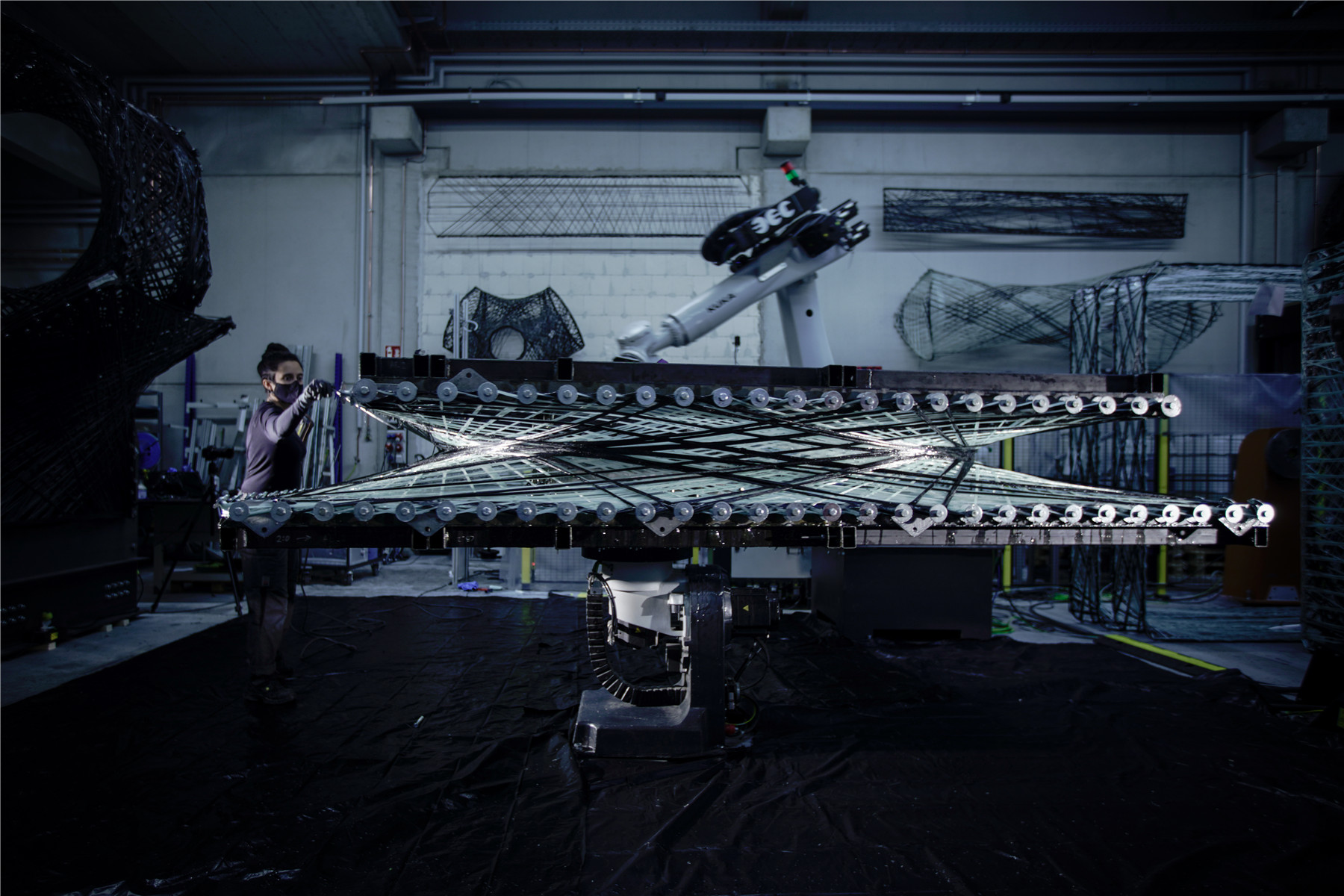

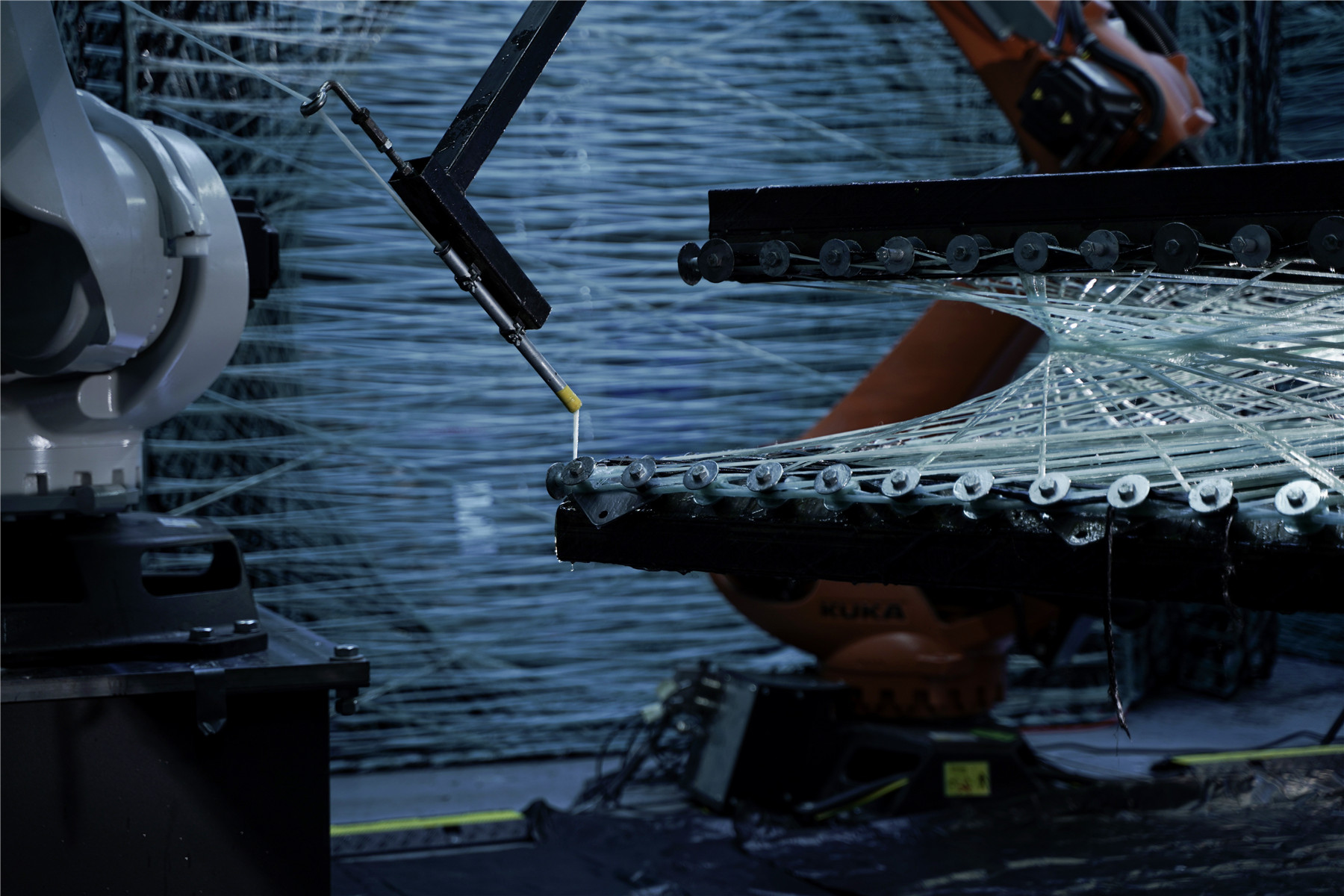

纤维墙和天花板元件是由项目团队开发的机器人无芯缠绕工艺制造的,它允许适应本地条件的负载设计和纤维排列,从而实现了一个特别轻的结构:符合结构规范的上层的承重纤维,重量仅为9.9公斤/平方米。墙的元件更轻。

The fibrous wall and ceiling elements were manufactured using the coreless, robotic winding process developed by the project team, which allows for locally load-adapted design and alignment of the fibers, thus enabling an extraordinary lightweight construction: The code-compliant, load-bearing fiber structure of the upper floor weighs just 9,9 kg/m². The wall elements are even lighter.

对于承重地板元件的制造,需要的材料体积小于组件体积的2%。这种极低的材料消耗,加上非常紧凑的机器人生产单元,在未来可以在没有大量噪音和浪费的情况下,进行整体的现场生产。这不仅可应用于最初的施工过程,也应用于扩建或改造过程。因此,使用这种方法构建的建筑将在长期内保持适应性和灵活性。

For the fabrication of a load-bearing floor element, less than two percent of the component volume is required as material volume. This extremely low material consumption coupled with the very compact, robotic production unit could in the future make it possible to carry out the entire production on-site without a significant amount of noise or waste, not only during the initial construction process, but also during expansion or conversions. As a result, architecture built using this method will remain adaptable and flexible in the long term.

本项目研究的建筑方法可用于多种材料。虽然纤维屋目前仍主要利用玻璃和碳纤维系统,但已经有迹象标明,纤维材料在不久的将来会大量出现:矿物纤维系统能够承受极端温度应力,天然纤维系统以年为周期生长。这些物质化与物质性的讨论,与现有的建筑概念截然不同,在纤维屋上层的“物质化”和“物质性”展览部分向参观者展示。

The building methods investigated in this project can be used for a variety of materials. While Maison Fibre still largely makes use of the currently available glass and carbon fiber systems, there are already signs of a considerable expansion of the material spectrum in the near future, ranging from mineral fiber systems that can withstand extreme temperature stresses, to natural fiber systems that grow within an annual cycle. These approaches to the materialization and materiality of architecture, which differ significantly from established notions of building, are explained to visitors in the exhibition sections “Materialization Perspective” and “Materiality Perspective” housed on the upper floor of Maison Fibre.

设计图纸 ▽

完整项目信息

Project Team

IntCDC / ICD University of Stuttgart, Institute for Computational Design and Construction

Prof. Achim Menges

Niccolo Dambrosio, Katja Rinderspacher, Christoph Zechmeister

Rebeca Duque Estrada, Fabian Kannenberg, Christoph Schlopschnat

IntCDC / ITKE University of Stuttgart, Institute of Building Structures and Structural Design

Prof. Jan Knippers

Nikolas Früh, Marta Gil Pérez, Riccardo La Magna

Lab support: Aleksa Arsic, Sergej Klassen, Kai Stiefenhofer

Student Assistance: TzuYing Chen, Vanessa Costalonga Martins, Sacha Cutajar, Christo van der Hoven, Pei-Yi Huang, Madie Rasanani, Parisa Shafiee, Anand Nirbhaybhai Shah, Max Benjamin Zorn

In collaboration with: FibR GmbH, Stuttgart

Moritz Dörstelmann, Ondrej Kyjanek, Philipp Essers, Philipp Gülke

with support of: Erik Zanetti, Elpiza Kolo, Prateek Bajpai, Jamiel Abubaker, Konstantinos Doumanis, Julian Fial, Sergio Maggiulli

Project Support

University of Stuttgart

Cluster of Excellence IntCDC, EXC 2120

Ministry of Science, Research and the Arts, Baden-Württemberg

GETTYLAB, Teijin Carbon Europe GmbH, Elisabetta Cane with Bipaled s.r.l. – Annalisa Pastore, Trimble Solutions Germany GmbH

Project Data

Building System:

Two-story, robotically fabricated, load bearing glass- and carbon fiber composite structure made of 23 km of glass fibers total and 20 km of carbon fibers total

Dimensions Length/Width/Height:

10,00m / 11,78m / 5,76m

Floor Area:

125 m² total

62,5 m² per floor

Weight of load-bearing fiber composite structure:

9,9 kg/m² for inhabitable first floor

Weight of load-bearing fiber composite structure including 27 mm timber floor panels:

23,7 kg/m² for inhabitable first floor

Weight comparison to regular 200 mm thick concrete slab:

Load-bearing fiber composite structure: 50x lighter

Load-bearing fiber composite structure including timber floor panels: 21x lighter

Material Volume Ratio:

1,9% material volume per slab volume

版权声明:本文由斯图加特大学计算机设计与建造研究所、建筑结构与结构设计研究所授权有方编辑发布,欢迎转发,禁止以有方编辑版本转载。

投稿邮箱:media@archiposition.com

上一篇:MVRDV最新方案,将一购物中心改造为“玻璃山”

下一篇:阿姆斯特丹法院新楼:经典外观与开放内核 / KAAN Architecten