设计单位 ICD/ITKE University of Stuttgart

项目地址 德国乌尔巴赫

建成年份 2019

占地面积 50平方米

自成型木材构件

A unique Landmark Built from Self-Shaping Wood

乌尔巴赫塔是一个独特的木结构建筑,它的设计灵感来自一个自成型的弯曲木构件。这种自成型的弯曲源于木材本身的特性,即木材在自身含水量降低时会自发收缩。最初,这座14米的高塔的所有组成构件都是平面的,但是在技术干燥过程中自动转变为最终的曲面造型。

The Urbach Tower is a unique wood structure. The design of the tower emerges from a new self-shaping process of the curved wood components. Components for the 14 m tall tower are designed and manufactured in a flat state and transform autonomously into the final, programmed curved shapes during industry-standard technical drying.

设计团队通过当地可持续、可再生的建筑材料,为高性能、精妙的结构体量创造了一种全新的的建筑可能性。这一开创性的做法推动了木材生产行业的工艺创新,将一种需要重型机械来辅助加工的精细却耗能的机械制造工艺,转变为一种可以依靠材料自身来独立完成整个制造过程的工艺。

This opens up new and unexpected architectural possibilities for high performance and elegant structures, using a sustainable, renewable, and locally sourced building material. This pioneering development constitutes a paradigm shift in timber manufacturing from elaborate and energy-intensive mechanical forming processes that require heavy machinery to a process where the material shapes entirely by itself. This shape change is driven only by the wood’s characteristic shrinking during a decrease of moisture content.

乌尔巴赫塔是世界上第一个自成型的组件构成的建筑。它不仅向人们展示了一种新颖的制造方法和木结构,更在乌尔巴赫当地建造了一个地标性建筑,从而增强了游客的空间参与感和景观体验感。

The Urbach Tower constitutes the very first structure worldwide made from self-shaped, building-scale components. It not only showcases this innovative manufacturing approach and resultant novel timber structure; it also intensifies the visitors’ spatial involvement and landscape experience by providing a striking landmark building for the City of Urbach’s contribution to the Remstal Gartenschau 2019.

Rems山谷中独特的建筑地标

Unique architectural landmark for the Rems Valley

2016年,一部分著名德国建筑师为Remstal Gartenschau 2019设计了16个站点,乌尔巴赫塔便是其中之一。这些站点作为小型的永久性建筑,呼应了散落在风景优美的Rems山谷的传统白色小教堂。

The Urbach Tower is one of 16 stations designed by some of the most renowned German architects for the Remstal Gartenschau 2019. The stations are small, permanent buildings that evoke the traditional white chapels distributed in the fields and vineyards along the scenic Rems Valley.

这座14米高的塔体位于山谷中心地带一个显眼的山坡上,连接着好几个站点,提供了一个可以用来休息的庇护所,人们可以在塔内静思,也可以远眺山谷的景色。塔身独特的造型展示了木材这种传统建材的现代建筑表现形式,它向上的螺旋形状展示了自成型木材与生俱来的自然特性。

Located on a prominent hillside in the center of the valley, the 14 m tall tower is a striking landmark that visually connects several stations. It provides a place of shelter, internal reflection and outward view by revealing stunning vistas and framing the landscape. The distinctive form of the tower constitutes a truly contemporary architectural expression of the traditional construction material wood. It celebrates the innate and natural characteristics of self-shaped wood in its upwards spiraling shape.

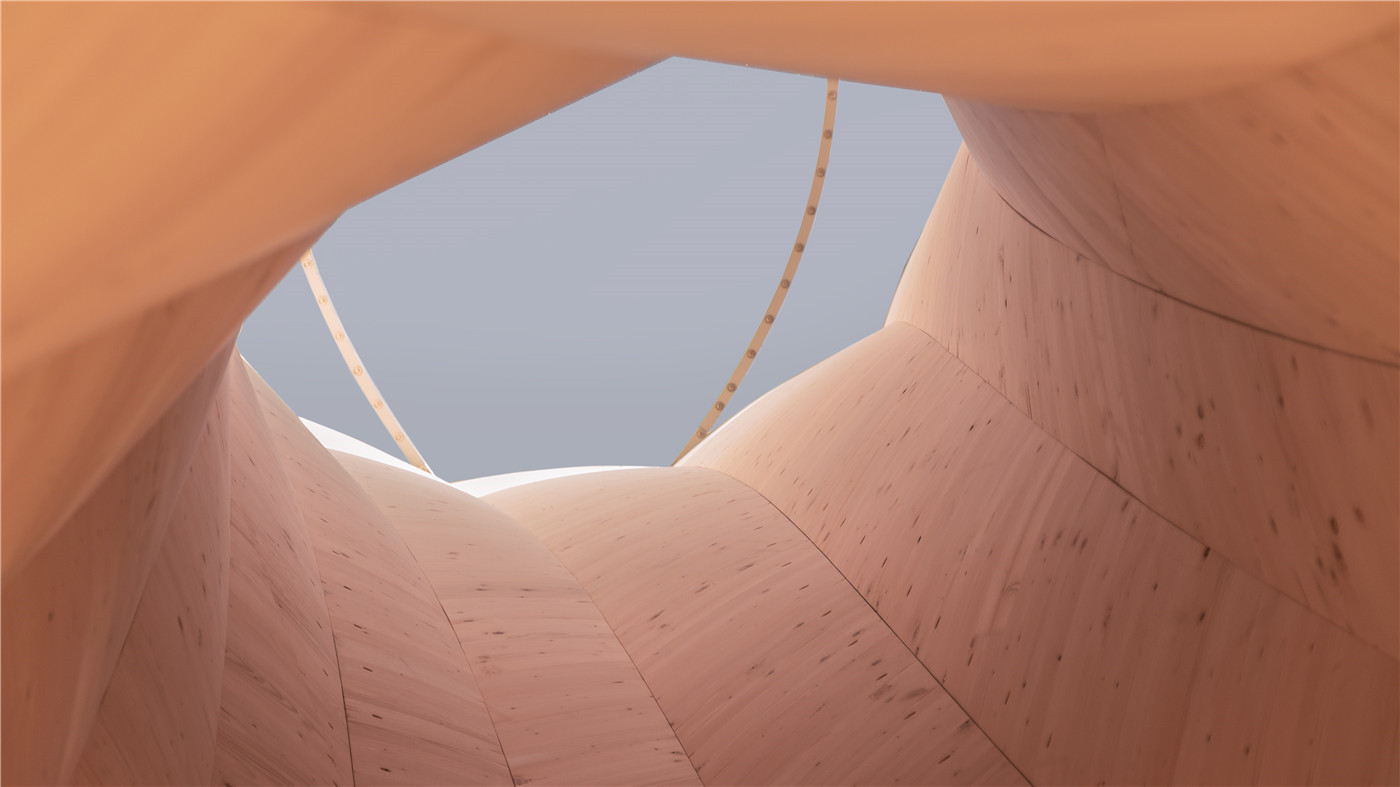

外部结构的凹陷形成了干净利落的轮廓线条和清晰的表面,而随着时间的推移,直射阳光和落叶松木覆层的白化过程更将进一步地加深这种凹陷。在塔体内部,木材结构看起来像纺织品一般柔软,而略微起伏的表面则进一步突出了这种轻柔感,内部凸起在视觉和触觉上创造出一种意想不到的材料体验。在塔身入口的对面,薄薄的木质外壳就像窗帘一样打开,将Rems山谷的美景置于视野的正中间。

The concave curvature of the structure on the outside results in sharp lines and crisp surfaces, which is further accentuated by direct day light and whitening of the larch cladding over time. In contrast, on the interior the convex curvature creates an unexpected visual and tactile material experience, with the timber structure appearing to be almost soft and textile-like, highlighted by the light washing the gently undulating surfaces. Opposite the entrance, the thin wood envelope opens like curtain, putting the Rems Valley on center stage.

机器算法决定木材形态

Material programming and predictability of shape change

木材的含水量变化通常会导致开裂和变形等问题,因此,工人必须谨慎控制木材中水分和压力的变化。在本项目中,建筑师巧妙利用了木材自发产生变形的特点,通过对机器的编程设计来使它们执行特定的运行命令,从而使得木材在干燥的过程中,逐渐转变为预设的形状,达到了一种自成型的设计效果。

In timber construction, moisture typically causes problems with cracking and deformation; hence, moisture changes and stress development must be carefully controlled. In contrast, in this project wood is programed and arranged in a way to utilize this powerful, naturally occurring deformation to trigger a designed self-shaping behavior. In the same way that machines can be programmed to perform different movements, wood parts can be programmed to transform into predetermined shapes when dried.

在研究和实践中,由于含水量变化所导致的木材变形规律是广为人知的。虽然将木材弯曲成不同的形状以达到结构和美观要求的方法已经存在了好几个世纪,并已经成为了一种普遍的工业制造方式,但它在很大程度上是依靠粗放型的机械生产方式来实现成型过程。然而,设计思维的转变以及机器算法的升级,使我们可以利用这种由含水量变化引起的膨胀和收缩特性,来设计和规划一种更大尺度、特定的自成型项目。

While methods of bending wood into different shapes for structure and aesthetics have existed for centuries and have become recognized industrial processes, they still mostly rely on brute mechanical force for the shaping process. Similarly, an understanding of how wood deforms due to changes in moisture content is well known in practice and academics. However, a shift in design thinking, as well as new computational simulations for more accurate prediction, now allow us to use this moisture induced swelling and shrinking to design and program specific self-shaping movements at larger and larger scale.

可持续木结构和功能性表皮

Sustainable wood construction and functional timber cladding

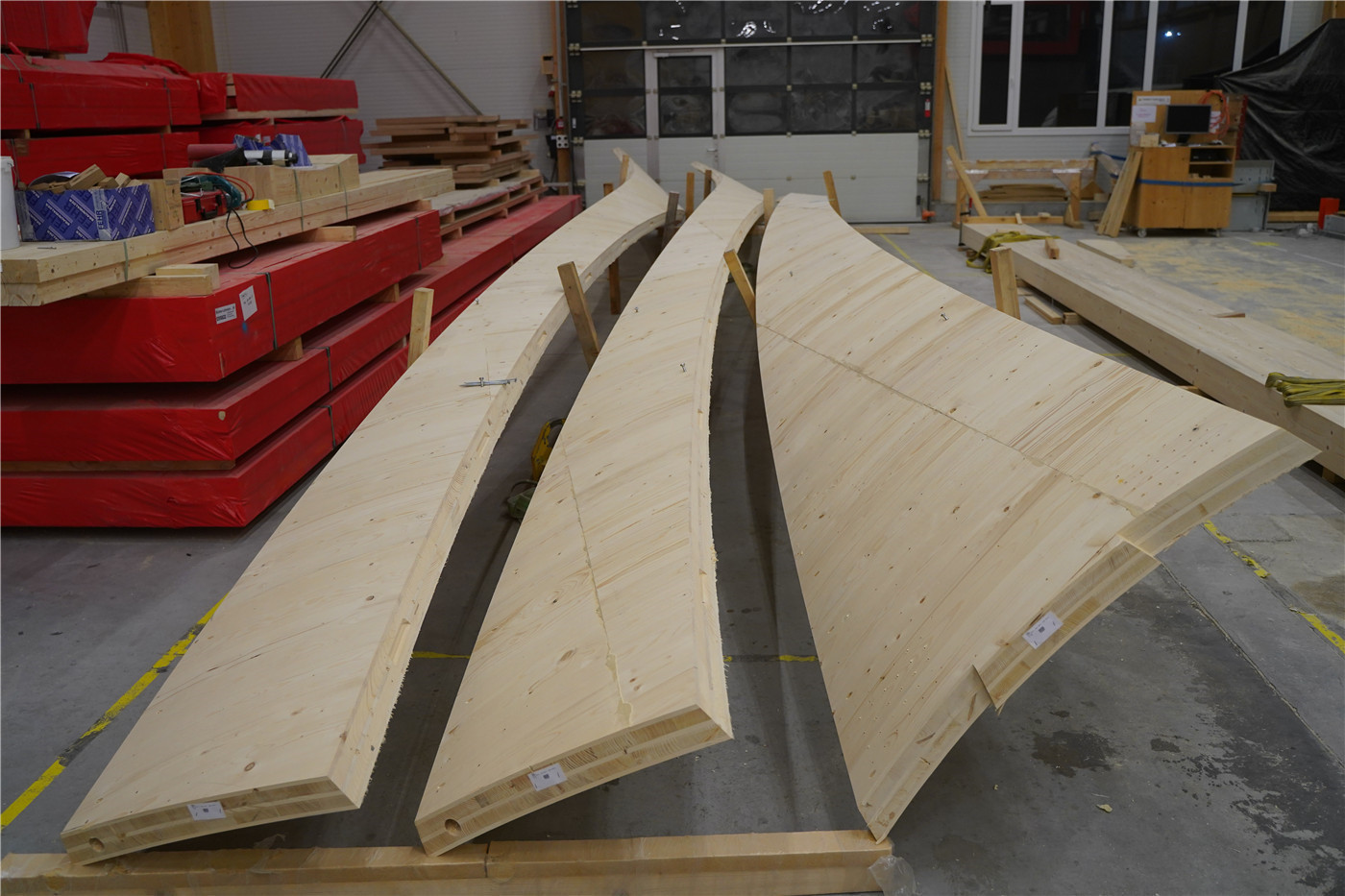

自成型构件由来自瑞士的云杉木板制成。木板变形后,单个构件的半径为2.4米,跨度可以达到15米,在这种情况下,结构厚度仅为90毫米。这些构件都是使用5轴CNC技术切割而成的,采用半圆柱坯料进行详细设计。

The self-shaping components are made entirely of spruce wood boards sourced regionally from Switzerland. Individual components span up to 15 m with a radius of 2.40 m and a structural thickness of only 90 mm. The components are 5-Axis CNC cut and detailed from half cylinder blanks and pre-assembled into building groups of three components for transport, including water barrier and external wood cladding.

建筑师将塔身预先拆分,组装成包括防水层和外部木材表皮在内的建筑构件群组,以方便运输。通过精确的曲率计算和纤维最优化处理,每个组件的所需的机器切割时间平均为90分钟。

With precise curvature and optimal fiber alignment from the manufacturing process, each component is cut in detailed in just 90 minutes of machine time.

此外,建筑师还在组件外侧覆上了由胶合层压落叶松木材打造而成的定制保护覆层。这个保护覆层中还包括一种透明且持久的无机涂层,可以保护木材免受紫外线辐射和真菌侵袭。并且,在室外环境中,落叶松木材不会开裂且逐渐变为银灰色,随着时间的流逝而呈现出一种均匀的白色。

A custom-made protective cladding layer consisting of glue laminated larch wood is added on the outside. This also includes the application of a transparent and durable inorganic coating, which protects the wood from UV radiation and fungi attack. Instead of ripping and turning silver-grey when exposed to outdoor weathering, the larch wood will take on an even white color over time.

从在锯木厂中切割当地的原木料,到自成型板的生产,到干燥过程,再到最终的加工和预组装过程等,整个工艺链都由同一群公司负责,在同一个地点进行。这不仅可以实现一种可持续创新性的生产机制,同时还展示了木材自成型制造工艺是如何无缝整合到已建立的工业木材加工和制造流程中的。

The entire process chain, from cutting regional logs in the sawmill to the production of the self-shaping panels, the drying process and final machining and pre-assembly takes place within the same group of companies and at the same location. This not only allows for sustainable and innovative production, but it also shows, how the self-shaping manufacturing can seamlessly integrate in established industrial wood processing and manufacturing workflows.

自成型制造过程

Self-shaping manufacturing at building-scale

在最初的设计和制造中,这座塔的所有弯曲交叉层压木材(CLT)构件都是平面的;然后在干燥脱水的过程中,自动变形为预设好的弯曲形状。

This shape change is only driven by the wood’s characteristic shrinking during a decrease of moisture content. The curved Cross Laminated Timber (CLT) components for the tower’s structure are designed and produced as flat panels that deform autonomously into predicted curved shapes when dried.

5×1.2米的云杉木双层构件在制造时有着较高的含水量,经过特殊的绞合处理后,在工业标准下的技术干燥过程中自动转变为最终的曲线造型。当云杉木从干燥室中出来的时候,它就已经达到了精确的弯曲程度。

The 5.0 m x 1.2 m spruce wood bilayers parts are manufactured with a high wood moisture content and specific layups and dried in an industry standard technical drying process. When removed from the drying chamber the parts are precisely curved.

建筑师将这些部件重叠并层压在一起,从而在特定的位置限定出一个几何造型,再依靠这种形状稳定性的几何造型来形成较大尺度的弯曲CLT部件。

The parts are overlapped and laminated together to lock the geometry in place, forming larger curved CLT components with form stable geometry.

建筑师通过特定材料的力学计算模型,来设计、预测和优化材料的处理方式,从而产生特定的曲率类型和半径。通过使用当地可持续、可再生的材料,实心木板的自成型制造技术,以及制造工艺对不同曲率快速调整的能力,建筑团队为薄壳结构创造了一种全新的建筑可能性。在建筑规模尺度和承重木结构上,乌尔巴赫塔也是该技术的首次应用所创造出的实际建筑物。

Material specific computational mechanics models have been developed to both design, predict, and optimize the material arrangement required to produce different curvature types and radius. The technology of self-shaping manufacturing for solid timber boards and the rapid adaptability of the process to different curvatures open up new and unexpected architectural possibilities for thin shell wood structures, using a sustainable, renewable, and locally sourced building material. The Urbach Tower is the very first implementation of this technology on building-scale, load-bearing timber parts.

高性能的薄壳木结构

Thin-shell high-performance timber structure

乌尔巴赫塔由12个弯曲的构件组成,而这些构件都由交叉层压木板打造而成,塔身的承重结构的厚度仅为90毫米。同时,它有一个14米的悬臂结构,这就创造出一个约160:1的跨厚比。

The Urbach Tower consists of 12 curved components made from cross-laminated timber. The tower’s load-bearing structure exhibits a thickness of 90mm while cantilevering over 14 meters resulting in a span to thickness ration of approximately 160/1.

曲率创造出一个纤细且轻质的塔体结构,表面每平方米自重仅有38千克。组装后,塔体的弯曲几何造型富有表现力,轻质的建筑元件通过左右螺丝连接。建筑师根据功能要求对螺丝进行了特定布置,选取最佳角度,使这些螺丝在整个建筑结构中最大限度地发挥自己的作用,同时,这种处理方法能够保持接缝处的连接性,从而实现均匀的荷载传递。

The inherent curvature enables a highly slender and lightweight tower structure of only 38 kg per square meter surface area. In the assembled state, the tower acts as a surface-active structure through its expressive curved geometry. The lightweight building elements are connected by crossing screws, the arrangement and specific angle of which is optimised throughout the structure in relation to their utilization while preserving a continuous connection along the seam for homogeneous load transfers.

塔体的预制装配分组进行,每组都由三个弯曲的构件组成。四名工匠组成一个团队,在不使用大量脚手架或是建筑模板的情况下,一个工作日便能完成组装过程,甚至还能在塔体顶部覆盖一层透明的屋顶。这个结构由大师级工艺、数字化创新和科学研究共同完成,展示了木结构在高效、经济、生态和表现力等方面的可能性。

The prefabricated assembly groups of the tower, each consisting of three curved components, were assembled in a single working day by a team of four craftsmen without the requirement of extensive scaffolding or formwork, and topped-off by a transparent roof. The structure showcases the possibilities for efficient, economical, ecological and expressive wood architecture that arises at the intersection of master craft, digital innovation and scientific research.

完整项目信息

Project Team:

ICD – Institute for Computational Design and Construction, University of Stuttgart

Prof. Achim Menges, Dylan Wood

Architectural Design

Self-forming Curved Wooden Components Research and Development

ITKE – Institute of Building Structures and Structural Design, University of Stuttgart

Prof. Jan Knippers, Simon Bechert, Lotte Aldinger

Structural Design and Engineering

Scientific collaboration:

Laboratory of Cellulose and Wood Materials, Empa (Swiss Federal Laboratories for Materials Science and Technology), Switzerland & Wood Materials Science, ETH Zurich (Swiss Federal Institute of Technology Zurich)

Dr. Markus Rüggeberg, Philippe Grönquist, Prof. Ingo Burgert

Self-forming Curved Wooden Components Research and Development (PI)

Industry collaboration:

Blumer-Lehmann AG, Gossau, Switzerland

Katharina Lehmann, David Riggenbach

Self-forming Curved Wooden Components Research and Development,

Wood Manufacturing and Construction

Project Support:

Gemeinde Urbach

Remstal Gartenschau 2019 GmbH

German Federal Environmental Foundation (Design, Fabrication and Engineering Methods for the application of curved wood elements in high-performance, resource-efficient wood construction: Project Tower Urbach, Remstal Gartenschau 2019)

Innosuisse – Swiss Innovation Agency (Smart, Innovative Manufacturing of Curved Wooden Components for Architecture with Complex Geometry)

Carlisle Construction Materials GmbH

Scanntronik Mugrauer GmbH

Project Data:

Dimensions

• 14.20m tall timber structure

• 4.0m radius bottom, 3.0m radius top, 1.6m radius middle

• Spruce Wood CLT with 10-30-10-30-10 build up

• Larche Wood façade with titanium oxide surface treatment

• 5 axis CNC cut components

• 12 individual prefabricated components pre-assembled in groups of 3

• Crossing screw connection detail with wood alignment blocks

• 8 Sensors to monitor internal WMC of the structure

Construction System:

Curved surface active tower structure, self-shaped curved cross laminated spruce timber (CLT) 10 -30-10-30-10 layup, glue laminated Larch façade with titanium oxide UV protection surface treatment, curved polycarbonate roof with steel support structure.

版权声明:本文由ICD-Uni Stuttgart授权有方发布,欢迎转发,禁止以有方编辑版本转载。

投稿邮箱:media@archiposition.com

上一篇:有方 × 一言一吾 | 刘珩:在那,我们都是气定神闲的赶路人

下一篇:建筑语言讲述现代办公:中建钢构总部大厦 / 中国建筑东北设计研究院有限公司(深圳)