设计单位 HANNAH

项目地点 美国,纽约州

建成时间 2019年

本文英文原文由设计单位提供。

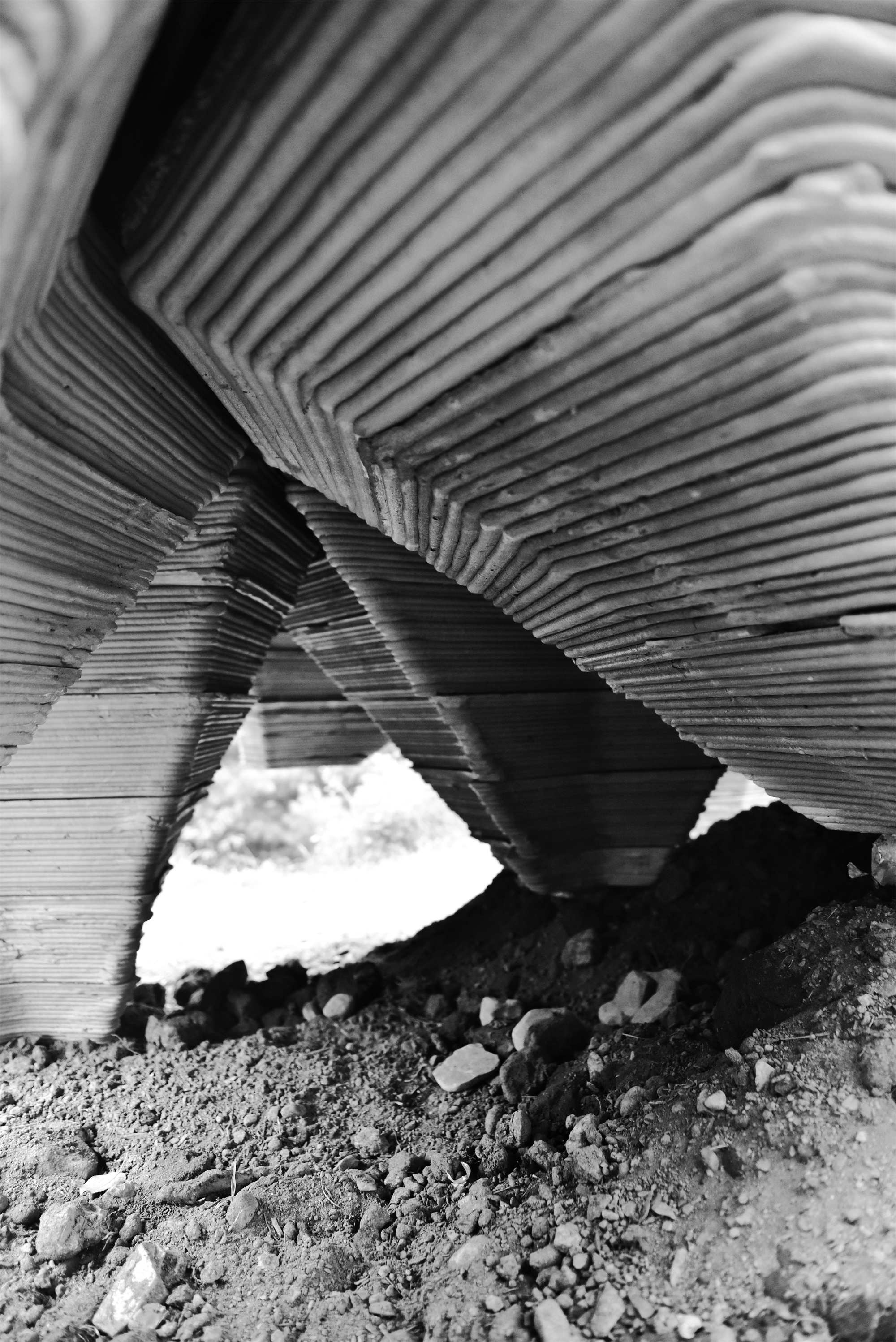

利用混凝土3D打印技术和被虫蛀侵害的木材,康奈尔大学建筑系公布了一项尖端可持续建筑建造工艺。其独特的设计结合了以往无法被使用的白蜡木、3D打印以及再利用汽车行业中的机械建造技术,为未来的房屋建造创造了一个模板。

Cornell University Architecture Faculty Unveil Cutting-Edge, Sustainable Construction Process Using Concrete 3D Printer and Lumber Devastated by Invasive Beetle. Unique design combines previously unusable ash wood, 3D printing, and repurposed automotive robotics to create a template for how future homes could be built.

▲ 项目视频 ©HANNAH

这项创造性的关键技术,主要针对于白蜡窄吉丁。白蜡窄吉丁是一种入侵物种,正在毁坏全美国各地的原生白蜡树。白蜡窄吉丁被认为是在2002年夏天通过人类贸易和旅行流入美国森林,如今,全美87亿棵树木,包括纽约州近十分之一的白蜡树都受其威胁。

Ithaca, NY, May 5, 2020 – The College of Architecture, Art, and Planning at Cornell University announce an important step in their creative and critical response to the Emerald Ash Borer beetle, an invasive species devastating native Ash trees across the country. The Emerald Ash Borer is thought to have been introduced to American forests via human trade and travel in the summer of 2002, and today threatens 8.7 billion trees across the country and nearly one in ten Ash trees in New York state.

康奈尔大学的建筑学助理教授,兼设计公司HANNAH的联合负责人LeslieLok和SasaZivkovic,在纽约州北部的村庄设计并建造了一个全尺寸的木屋原型,以应对环境危机,并推进了机械建造和3D打印等技术在木材和混凝土建筑中的应用。

Leslie Lok and Sasa Zivkovic, both assistant professors of architecture at Cornell and co-principals of their design firm, HANNAH, have designed and constructed a full-scale prototype cabin home in rural Upstate New York that responds to the environmental crisis, and, advances the use of technologies such as robotics and 3D printing in timber and concrete construction.

Lok表示:“我们相信这个原型提供了一种思考未来住宅建造的新方法。这个小屋结合了我们的设计的研究和思考,以在自然环境现状危急的情况下探索我们可能的干预模式。而且,它展示了一种可复制推广的、较新的科技手段,让我们得以在建筑学科中推动形式上和技术上的创新。”

“We believe this prototype offers a new way to think about the future of home construction,” said Lok. “The cabin is a combination of our design research and thinking in response to the urgent condition of our natural environment and possible modes of intervention — and, it demonstrates our potentially replicable use of relatively new technologies that allow us to advance both formal and technological innovation in the [architecture] discipline."

垂死的白蜡树,再造一种新的 "废料"

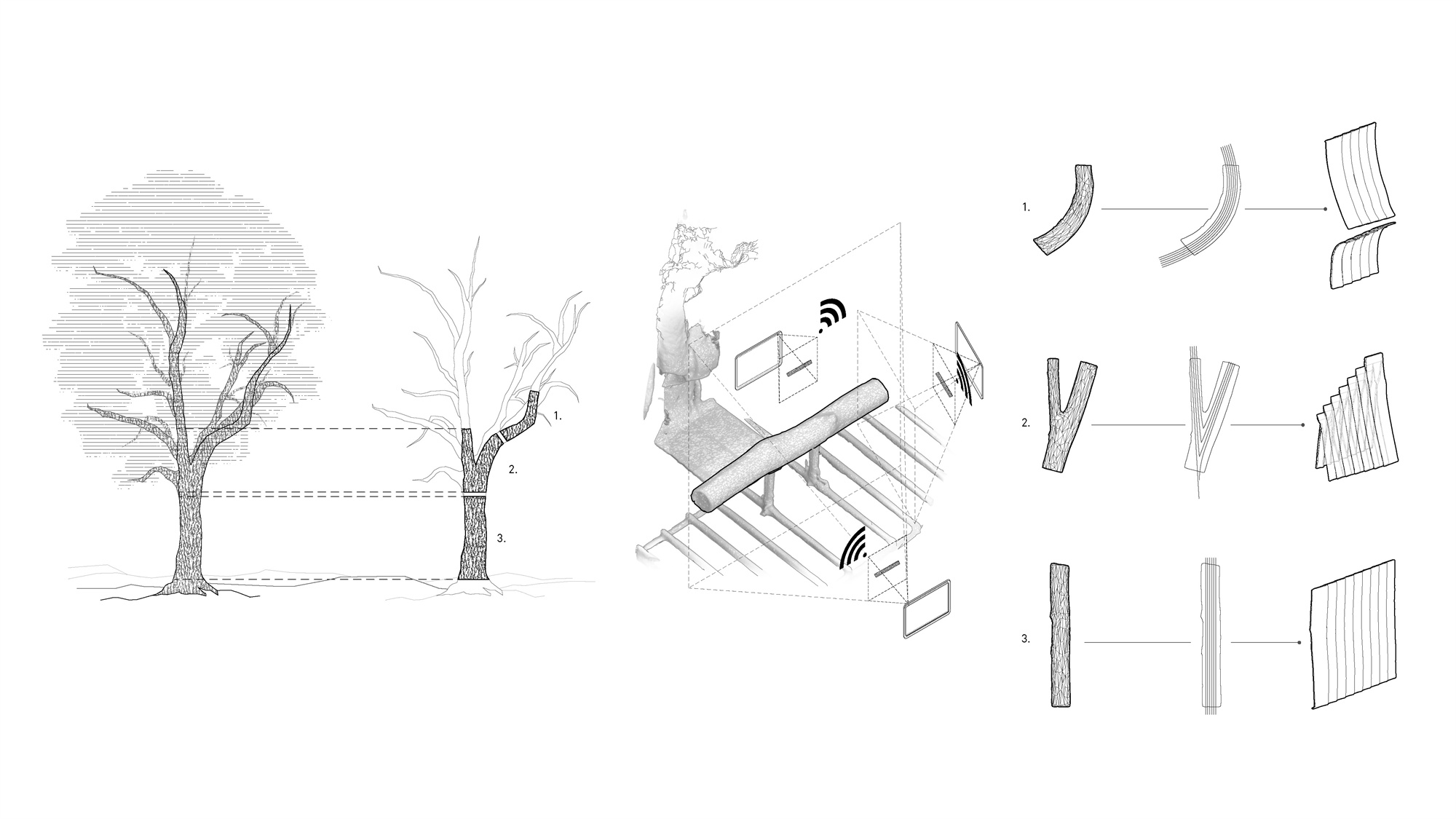

由于其几何形状不规则,被白蜡窄吉丁伤害的成熟白蜡树目前还不能被传统的锯木厂用作房屋建材。

Until recently, mature ash trees compromised by the Ash Borer have not been usable by conventional sawmills as a source of lumber for home construction in part because of their irregular geometries.

Zivkovic称:“受侵害的白蜡树通常要么被分解,要么被烧掉作为能源。不幸的是,这两种情况都会造成二氧化碳排放。因此,使用受损的白蜡树进行建造的好处是,它既能将碳牢牢锁在地球上,又能抵消对常用的木材品种的砍伐。受感染的白蜡树是一种特定的‘废料’形式。如今白蜡病如此普遍,所以我们无法遏制它,但我们可以制定一种策略,将它们作为一种材料资源来利用。”

“Infested ash trees often either decompose or are burned for energy,” said Zivkovic. “Unfortunately, both scenarios release CO2 into the atmosphere, and so the advantage to using compromised ash for construction is that it both binds the carbon to the earth and offsets the harvesting of more commonly used wood species.”

“Infested ash trees are a very specific form of 'waste material' and our inability to contain the blight has made them so abundant that we can — and should, develop strategies to use them as a material resource,” he added.

使机器人技术和混凝土3D打印成为可能性

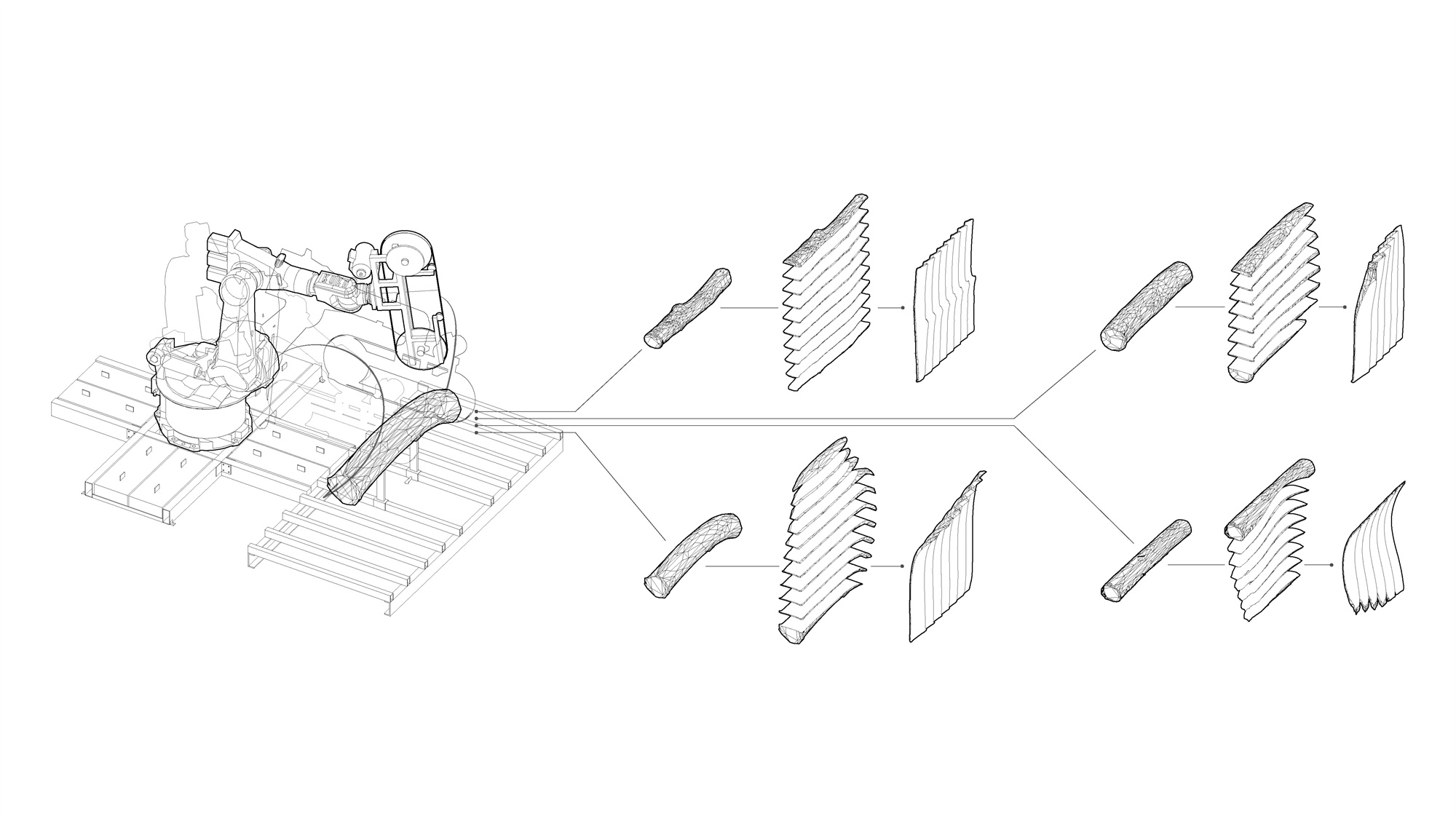

与时俱进的技术——特别是机械建造和混凝土3D打印技术——以及它们在建筑设计学科和建造行业中的应用,使得用被虫蛀侵害的白蜡树作为建材成为可能。作为康奈尔大学机械建造实验室(RCL)的主任Zivkovic,与团队建立了一个定制的机械平台,就是为了处理这些不规则的白蜡树。

Consistently advancing technologies — specifically robotics and 3D printed concrete — and their use in the architectural design discipline and construction industries make the use of infested ash trees possible. Zivkovic is director of the Robotic Construction Lab (RCL) at Cornell, where the team built a custom robotic platform for the sole purpose of processing the irregular ash trees.

“RCL的团队为专门处理不规则白蜡树建立了机械平台。首先,我们对木材进行3D扫描,作为转译和数字化成熟树木复杂且不规则几何形状的基础步骤;然后对机器进行编程,对不规则的木材进行切割和加工——正是通过现有的这些技术,我们得以对这种材料进行加工处理。”Zivkovic解释说。

"The team at RCL built the robotic platform specifically for processing irregular ash trees. Basically, we begin by creating 3D scans as a basis for translating and digitizing the complex and irregular geometries of the mature trees. The robot is then programmed to cut and process irregular wood geometries — it is through these current technologies that we can work with this material," explains Zivkovic.

团队使用的机械臂是在eBay上发现的,曾用于通用汽车公司的汽车生产。Zivkovic和RCL团队利用这个机器,并通过对其进行重新编程,使得它根据木材的结构和设计元素的规模,有条不紊地锯开塑形木材。

The robotic arm they use was discovered on eBay and previously built cars for General Motors. Zivkovic and the RCL team repurposed the robot, reprogramming it to methodically saw and shape the wood at a scale usable for structural and design elements.

基于混凝土是如今使用最广泛的建筑材料之一,康奈尔大学的研究人员开发了全尺寸3D打印系统,该技术不需要模板,在生产过程中使用最少量的混凝土。这不仅节省了大量的材料,还大大改善了混凝土建筑中的二氧化碳产生。

In response to the use of concrete, one of the most widely used building material on earth, the Cornell researchers developed the full-scale 3D printing system that requires no formwork and uses the absolute minimum amount of concrete in the production process. This saves a significant amount of material, significantly improving the CO2 footprint of concrete construction.

Lok继续表示:“我们知道,混凝土的生产占二氧化碳总排放量的8%。通过混凝土3D打印的方式,我们消除了建造时模板使用而产生的浪费,并且只在结构需要的地方沉积混凝土,十分巧妙。这既大大减少混凝土的使用量,同时也保持了建筑的完整性。”

"We know that concrete is responsible for 8% of total CO2 emissions," explains Lok. "By using 3D printing, we eliminate the use of wasteful formwork and can deposit concrete smartly and only where structurally necessary, reducing its use considerably while also maintaining a building's integrity."

对未来的展望

这座小屋展示了在美国甚至更多的地方思考可持续住房设计、开发和建设的新方式。结合了美国最广泛使用的两种建筑材料(混凝土和木材)进行创造性的设计,也从根本上重新思考了使用这些材料的技术与方法。

The cabin demonstrates a new way to think about sustainable housing design, development, and construction in the United States and perhaps beyond. Its inventive design combines two of the most widely used construction materials in the US (concrete and timber), rethinking techniques and approaches for using them from the ground up.

其他行业已经从日益更新的技术中受益匪浅,这些技术使生产更加高效,资源消耗更少。然而,住宅建筑业几十年来一直没有变化。在当前的气候紧急的情况下,Lok和Zivkovic研究和开发的设计语言,为未来建造的可能性提供了一个强有力的参考。建筑师、工程师和建筑专业人士可以直接利用从实验室或工作室产出的原型——适用于未来的迭代测试、持续的批判性思维和投机设计。

Other industries have benefited enormously from disruptive technologies that make production more efficient and less resource intensive. The residential construction industry, however, has remained unchanged for decades. Lok and Zivkovic's research and development of a design language informed by the context of the current climate emergency make a strong case for a possible future where architects, engineers, and construction professionals can benefit directly from prototypes that emerge from labs or studios geared for iterative testing, sustained critical thinking, and speculative design.

该项目结合了对环境的关注和对先进技术的创造性使用,有望激发出富有想象力的设计,提高建筑中的材料使用效率,降低长期建设的成本,并增加分配式制造工具的可用性和通用性,为未来房主们提供前所未有的大规模定制的可能性。

The project’s combined environmental concern and inventive use of advancing technologies promises to inspire imaginative design, improve material efficiency in construction, reduce long-term construction costs, and increase the availability and versatility of tools for distributed manufacturing that offer unprecedented mass customization to future homeowners.

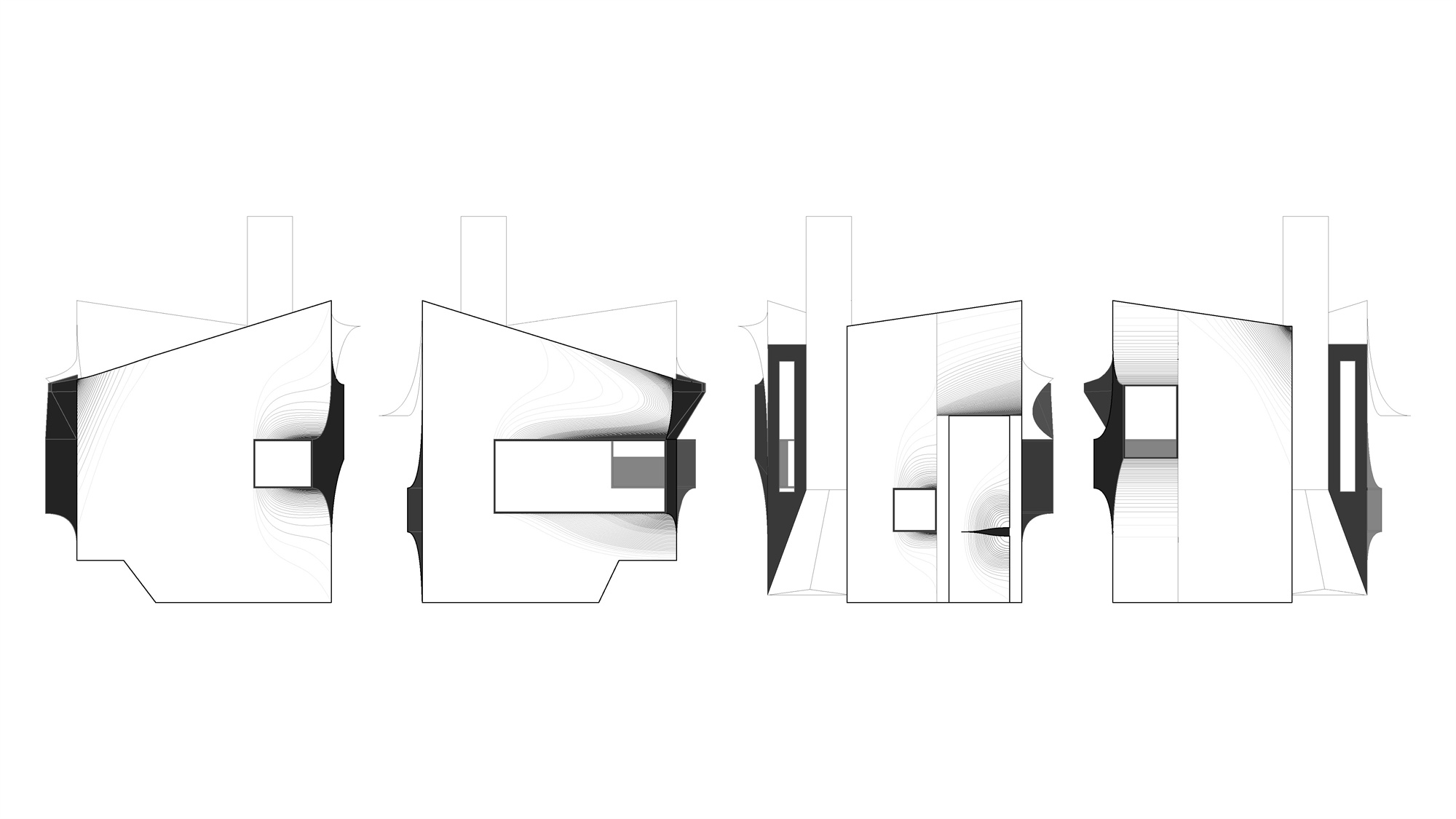

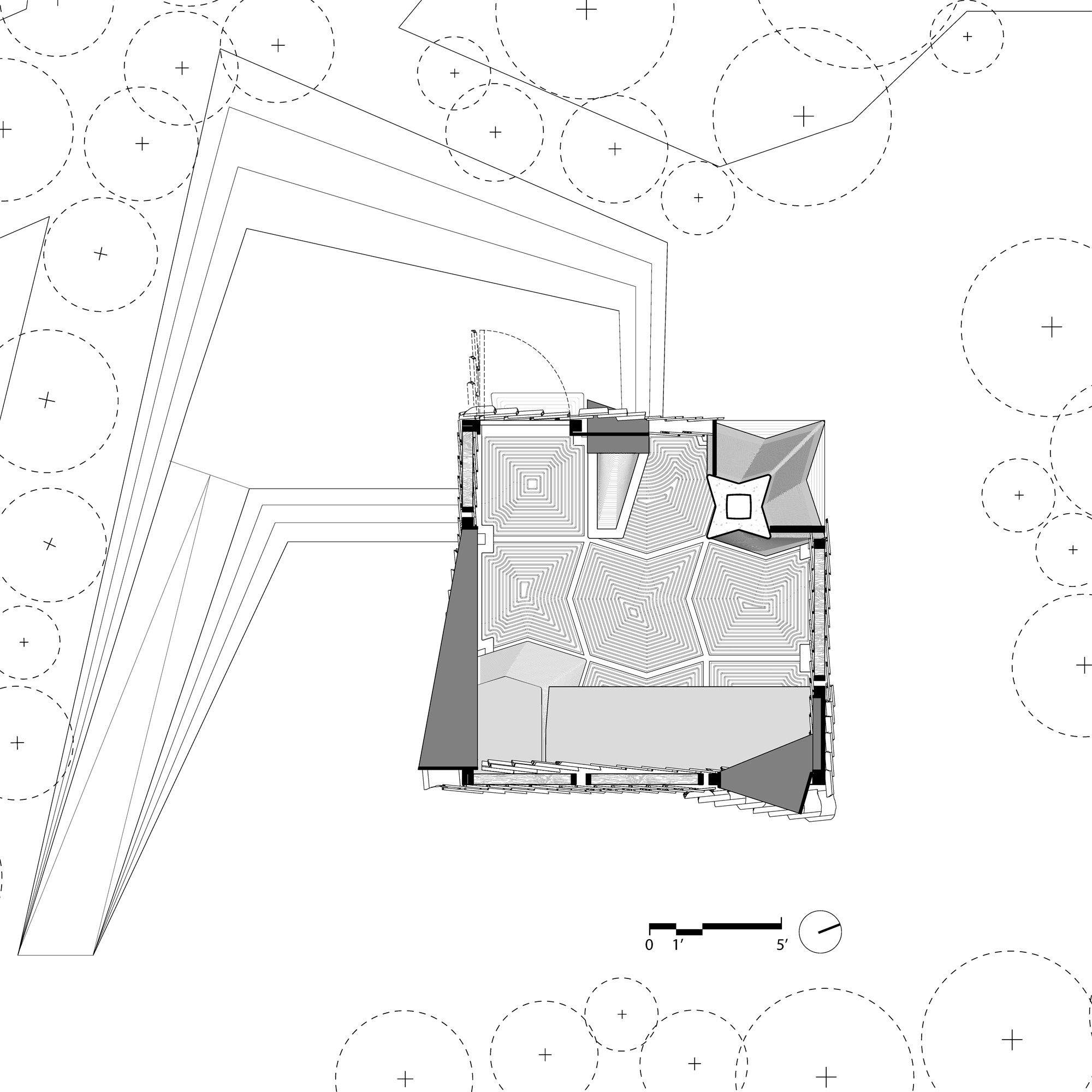

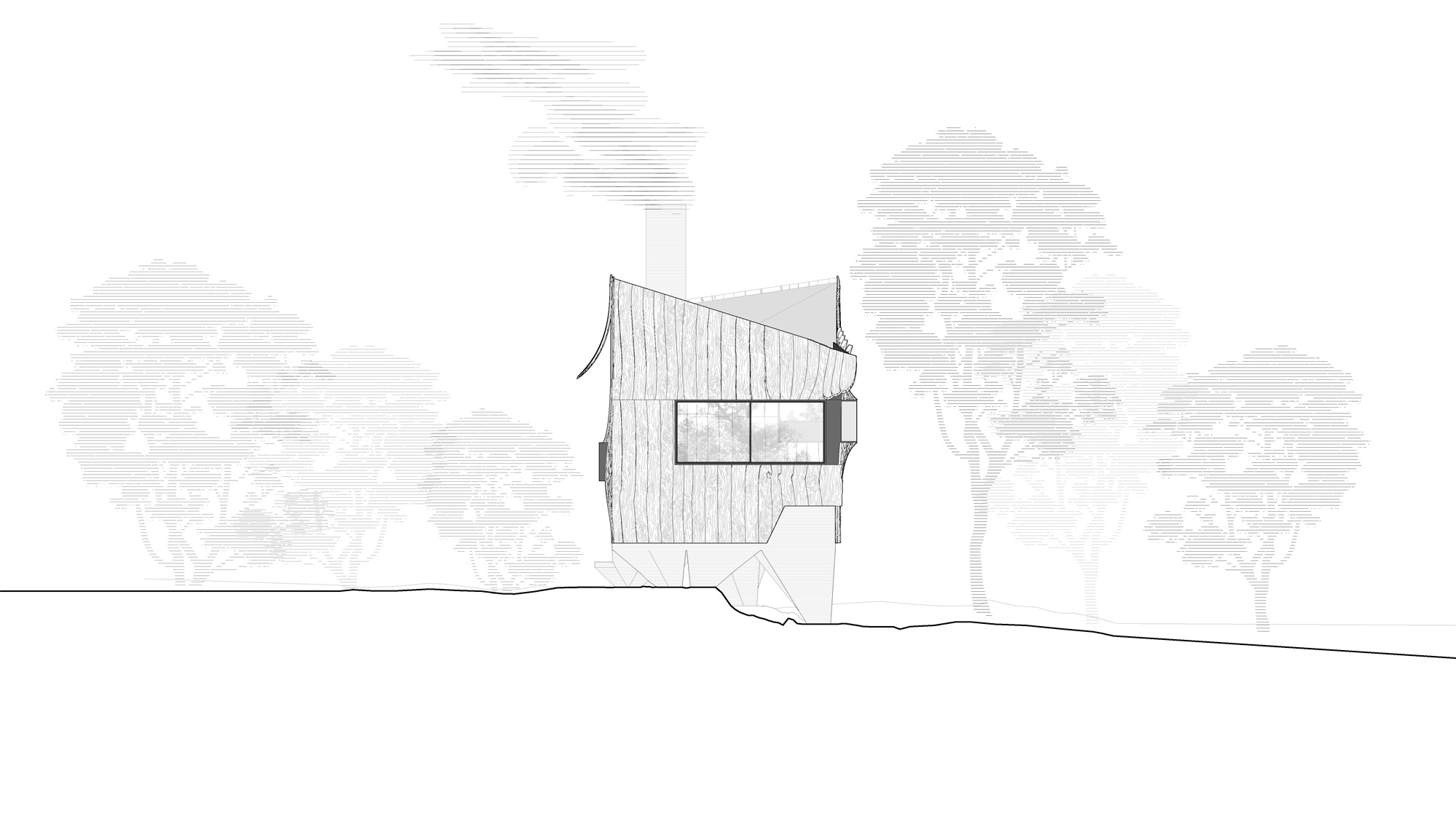

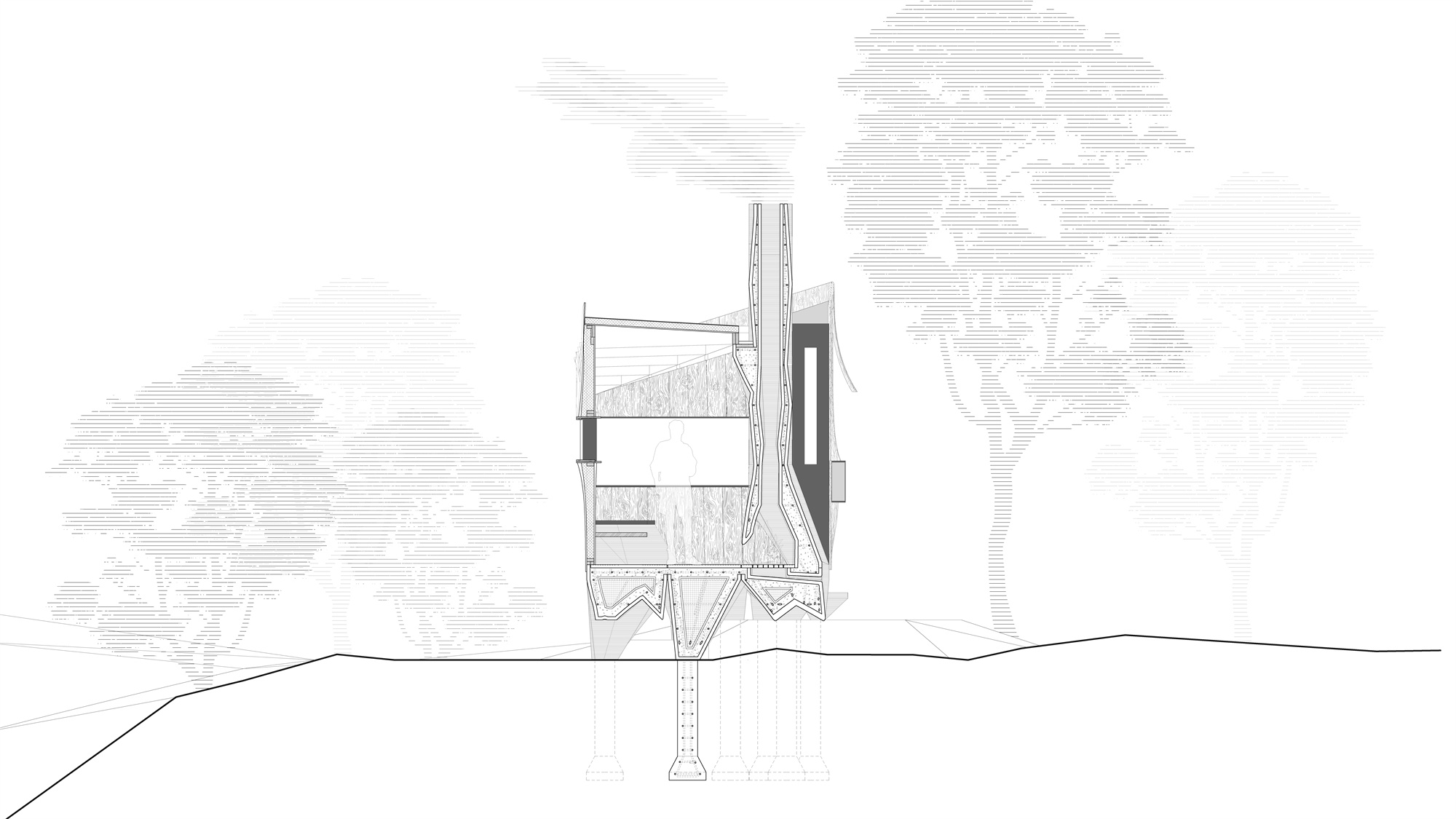

设计图纸 ▽

完整项目信息

HANNAH project leadership: Leslie Lok and Sasa Zivkovic (Principals)

Project team concrete: Christopher Battaglia, Jeremy Bilotti, Elie Boutros, Reuben Chen, Justin Hazelwood, Mitchie Qiao / Assembly and documentation team concrete: Alexandre Mecattaf, Ethan Davis, Russell Southard, Dax Simitch Warke, Ramses Gonzales, Wangda Zhu / Project team wood fabrication and design: Byungchan Ahn, Alexander Terry / Wood studies: Xiaoxue Ma, Alexandre Mecattaf / Assembly and documentation team wood: Freddo Daneshvaran, Ramses Gonzalez, Jiaying Wei, Jiayi Xing, Xiaohang Yan, Sarah Elizabeth Bujnowski, Eleanor Jane Krause, Todd Petrie, Isabel Lucia Branas Jarque, Xiaoxue Ma / Representation team: Byungchan Ahn, Kun Bi, Brian Havener, Lingzhe Lu / Cornell Arnot Teaching and Research Forest: Peter Smallidge (Arnot Forest Director)

Project realized with scientific support from the Cornell Robotic Construction Laboratory (RCL) / Sponsors: AAP College of Architecture, Art, and Planning; AAP Department of Architecture; HY-Flex Corporation; Cornell Atkinson Center for a Sustainable Future, Cornell Arnot Teaching and Research Forest

版权声明:本文由HANNAH授权发布。欢迎转发,禁止以有方编辑版本转载。

投稿邮箱:media@archiposition.com

上一篇:NGV当代艺术馆 | Angelo Candalepas and Associates联合团队

下一篇:正交变幻:La Serenissima办公楼翻新 / Park Associati